Smithers pegs growth for USD 60.4 bn folding carton market

Smithers, in its latest market report – The Future of Folding Cartons to 2028 states the actual consumption of paperboard formats will reach 56.8 million tons worldwide, up from 47.8 million tons in 2019. And in 2028, it will be 77.3 million tons which is equivalent to a compound annual growth rate (CAGR) of +6.4%.

07 Jul 2023 | 2512 Views | By Charmiane Alexander

Sustainability holds the key, according to the latest data from Smithers. And the industry response to this will push growth in sales of cartonboard, microflute and miniflute packaging. The consumption numbers for 2023 for paperboard formats will reach a projected 56.8 million tons worldwide, up from 47.8 million tons in 2019.

The latest market report from Smithers – The Future of Folding Cartons to 2028 – shows this will reach 77.3 million tons in 2028, equivalent to a compound annual growth rate (CAGR) of +6.4%.

Across the same period the value of carton board will increase from USD 60.4 billion to USD 79.7 billion (at constant prices), equivalent to a CAGR of +5.7%.

A total of over six million tons of production capacity entered the market between 2020 and 2022

Meanwhile, the global value of converted folding carton packaging will reach to USD 274.5 billion in 2028 from the current ebaluation of 199 billion in 2023.

An analysis of Smithers’ extensive data shows how folding carton use remains split between food and beverage, and other applications. Much of the growth is coming from evolving existing paper technologies to replace plastics, supported by legislation, such as the forthcoming revision of the Packaging and Packaging Waste Directive in Europe. This includes new formats in fresh produce, food service, beverage multipacks, ready meals, home, and personal care.

A press note from Smithers said, “The fastest growing sectors across the next five years will be dry foods, confectionery, healthcare, personal care, and chilled food.” It added, “Acceptance in several of these is conditional on deploying improved coating technology to protect fibers from wet or fatty foods, and present a premium print surface.”

One key highlight in the report is, 70% of all carton board packaging carries a coating of some form. In 2023, 90% of these coatings by weight are thermoplastic polymers or aluminum, and there is a premium to develop for functional coatings that do not compromise fibre recyclability. And so, paper mills are taking steps to upgrade machines to enable or improve inline coating on the paper machine to meet the growing demand for these types of coated cartonboard.

Luxury packaging remains a major target for many suppliers, with new premium grades entering the market combining superior print surfaces, with greater recyclability credentials. This is stimulating greater demand for virgin pulp cartonboards. Simultaneously, there is an impetus to add smart tracking technology to folding cartons giving greater supply chain insight and protecting high-value goods against counterfeiting.

The market is also having to negotiate price disruption. Raw material prices rose by over 25% in 2022 following a 14% increase in 2021. In the short-term this is creating a febrile marketplace, even as new folding carton assets come online. A total of over six million tons of production capacity entered the market between 2020 and 2022, which gives a global installed capacity in 2022 of over 59 million tons, providing a buffer of some five million tons.

Paper mills, especially in Europe, are increasingly investing in more energy-efficient equipment and even trialing alternative pulp supplies. This is reflected in an increased consumption of uncoated recycled board (URB); although coated recycled board (CRB)/white-lined chipboard (WLC) and folding boxboard (FBB) will continue to represent the majority of the market.

Booming demand for dedicated eCommerce formats has translated into an acceleration of demand for microflute packaging, featuring a litho-laminated outer layer of cartonboard applied to the single-face corrugated under-layers. Over time it is anticipated that some of this cartonboard market will be eroded by the use of linerboard, thereby removing the need for a separate lamination process.

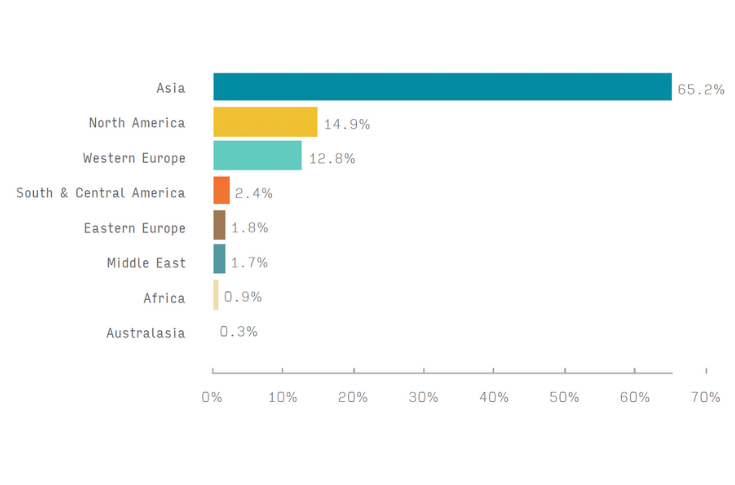

The Future of Folding Cartons to 2028 dissects the current and future market for this packaging type in forensic detail. Its exclusive data (by volume and value) is presented in over 350 tables and figures, segmenting the market by eight board grades and formats; 24 end-use applications, and 31 leading national and regional markets.

This report is available for purchase now.