More per metre is the mantra at UFlex

In an interview, Sumeet Arora, senior vice president, sales and marketing (engineering business), UFlex, shared what sets the company apart and ahead of its competitors.

09 Apr 2025 | By Sai Deepthi P

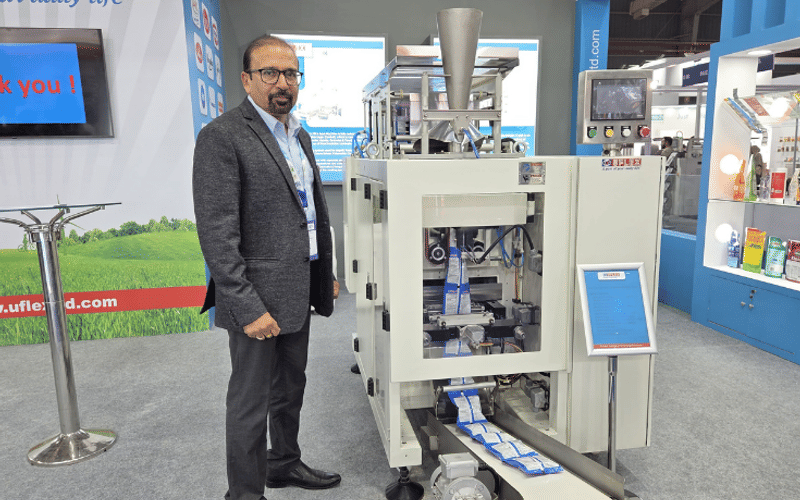

UFlex showcased two of its best-selling machines: the UFlex CT-140, a high-speed servo-driven vertical form-fill-seal machine, and the UFlex PFS-240, an automatic pick-fill-seal machine. In an interview, Sumeet Arora, senior vice president, sales and marketing (engineering business), UFlex, shared what sets the company apart and ahead of its competitors.

Sai Deepthi (SD): What’s on display?

Sumeet Arora (SA): Today, packaging is no longer just about enclosing a product. Three decades ago, it was mainly about ensuring safe delivery. Now, it plays a crucial role in extending the product's shelf life and enhancing functionality. We’ve displayed the vertical form-fill-seal machine, where the product is fed vertically into a formed bag. This machine runs at 140 bags per minute, making it one of the fastest on the market. It's also considered the "zenith of flexibility" in bagging, capable of handling a wide variety of products.

.png)

On the other hand, we have the automatic pick-fill-seal machine, one of the most exciting innovations in our portfolio. There is a growing trend toward using pre-made bags, which are not only visually appealing but also designed to be easy to open. Packaging today has evolved to offer product protection, longer shelf life, and consumer confidence, ensuring that buyers know they are purchasing a genuine product.

SD: What’s UFlex’s USP?

SA: Five to ten years ago, a speed of 100 bags per minute was considered a benchmark. We then collectively advanced to 120, and today, we are working toward achieving a solution that delivers 160 bags per minute. What gives UFlex a unique advantage is that we manufacture our own films. This allows us to tweak the laminate properties, such as tackiness, heat sealability, or thickness, to align with the machine speeds we aim to achieve. This vertical integration gives us a significant edge over competitors.

SD: What makes this machine special?

SA: When this technology was first introduced, most machines in the market were imported. UFlex machines, however, are 100% made in India.

SD: What are the challenges in developing a 100% Make in India machine?

SA: While there was no direct demand for a high-speed machine, we chose to take the initiative because we closely follow market trends and understand the evolving needs of our customers. If you were to rely on older machines, you might need 20 machines to meet your production targets. With our high-speed machines, you can do the same job with far fewer units, leading to substantial savings not just in capital investment, but also in floor space, utilities, manpower, and overall cost of ownership.

SD: What about sustainability?

SA: Sustainability is not just a trend—it’s a collective responsibility that requires action at every level. The environmental challenges around us, from littered streets to overflowing landfills and the growing concern of plastic waste, are clear reminders of the urgency. At UFlex, we believe that real change happens when awareness translates into action. UFlex is fully prepared to scale sustainable solutions and technologies, whether through innovation in recyclable packaging or investments in circular economy models. Our focus is on being solution-ready, always.

UFlex's pyramid of efficiency

Speed

Goal: Maximise output per square metre

Why? Fewer machines = lower costs (land, manpower, utilities)

Flexibility

Goal: Handle diverse products (shapes, sizes) on the same machine

Why? FMCG brands (e.g., Haldiram’s 1,000+ products) need adaptability

Accuracy

Goal: Zero giveaways; exact measurements (e.g., 40g = 40g)

Why? Profit protection + customer trust