UFlex continues product innovation with a focus on sustainability

The focus on research-led innovation and delivering on sustainability goals led to new product launches in Q4 FY2023. A compilation of UFlex’s new product developments from its various divisions such as films, flexible packaging, chemicals and cylinder business

01 Jun 2023 | By Abhay Avadhani

Packaging films business

The newly developed metallised polyester (F-ETB-M) film by the UFlex Packaging Films business addresses barrier requirements of various pouches and packaging applications while enabling easy-to-tear package properties from both directions.

The critical attributes of F-ETB-M include a special effect coated BOPET film, superior oxygen barrier, moisture barrier properties and a metal bond between the metal and the film.

The application areas of this film include; packaging items like mouth fresheners, tea sachets, confectionary items, biscuits, and multiple pharma and medical products. Such products require oxygen barriers for maintaining freshness and easy-to-tear packages for enhanced customer experience.

This transparent BOPET film is suitable for pouches and for quick and convenient packaging applications. The film addresses the barrier requirements with an easy-tear property in MD and TD directions for products sensitive to oxygen, moisture, and atmospheric conditions.

Flexible Packaging Business

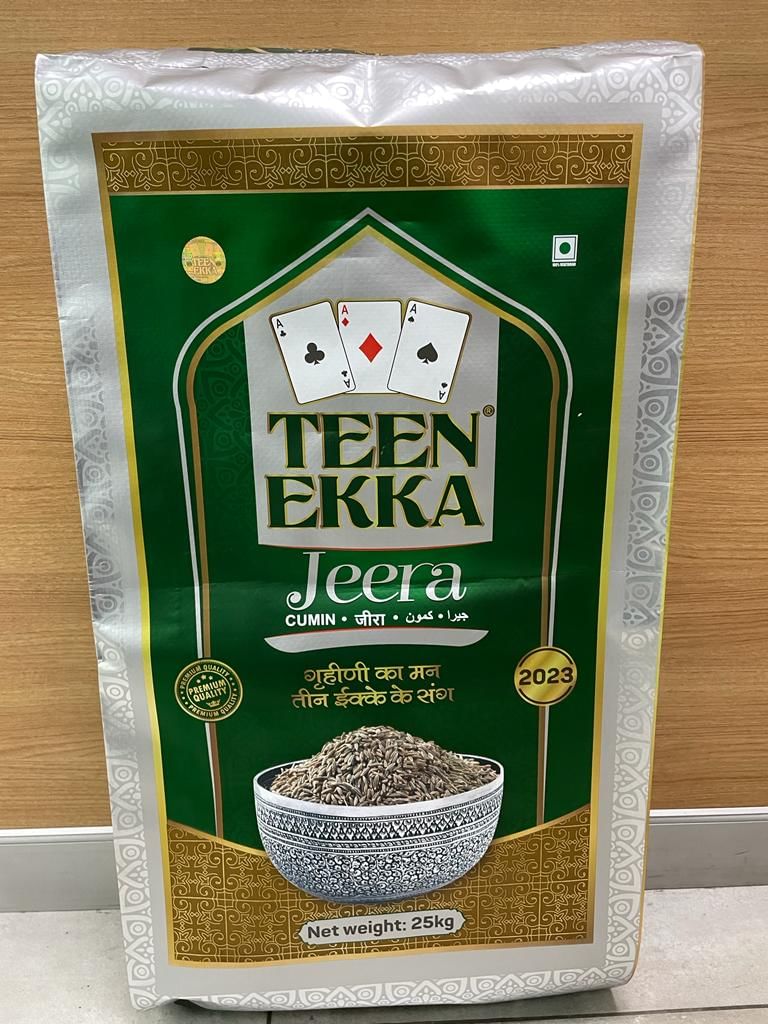

Teen Ikka jeera products were falling victim to counterfeit practices. To help the brand solve this problem, UFlex developed the WPP pinch bottom bag with foil stamping as an anti-counterfeit feature to prevent it from getting refilled or falling prey to counterfeiting.

UFlex also developed and converted the WPP bag of Dormulin fertiliser into a 3D pouch for a five kilogram of product quantity in Q4, FY23. This enhances the product’s packaging aesthetics and the packaging design for better display and appeal.

Chemicals Business

Epoxy Acrylate Oligomer developed by the UFlex Chemicals business is an environment-friendly product. It is an essential feedstock for radiation-curable coatings and printing inks manufactured by UFlex. The production process of this polymer is designed in a way that it generates no VOCs and effluents production process of this polymer is designed in a way that it generates no VOCs and effluents.

Polyester Acrylate

The polyester acrylate oligomer is a significant feedstock for UV and EB curable coatings and printing inks. This product is recommended for use in applications such as flexo, dry offset, screen printing, and wet lithographic inks for paper, plastics, and metals. It can also provide adhesion for metal, plastics, and paper coatings.

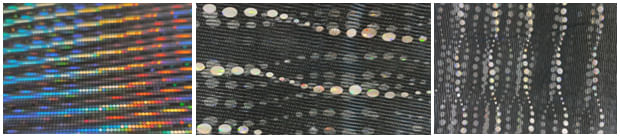

Holography Business

With a moving dot effect, the holography beads design offers a visually appealing option for hot-melt film and Sequins film used in various textile applications. The holography beads design developed by UFlex’s Holography Business provides an alternative to the popular lots of dots (LOD) design.

Replacing the LOD design with the holography beads design developed by UFlex will enable textile businesses to tap into a growing market segment of customers seeking a change from the standard holography designs. Additionally, the moving dots effects in this new design provide a dynamic and eye-catching appearance, enhancing the overall visual impact of the holographic film.

.jpg)

.jpg)

Chequered pattern hot stamping foil

The newly developed chequered pattern hot stamping foil enables an enhanced style of textile products. The chequered pattern has reflective properties and is available in a range of colours.

Chequered pattern hot stamping foil has applications across market segments such as fashion, home textiles, accessories, and upholstery.

Printing Cylinders Business

Carving Effect through laser embossing on PVC is an exciting new product from UFlex’s Printing Cylinders business. It can enhance the attractiveness and aesthetics of home interiors like modular kitchens, table covers, door mats, floor mats, and even in-car floor mats. It is durable, easy to maintain, cost-effective, and can be installed in a short time.

Engineering Business

Engineering Business design team has developed Accu Slit-3300, the new slitter of width 3,300 for slitting metallised BOPP and other substrates in Q4, FY23.