Spotlight: The ITP-60 photopolymer Macdermid plates at Multiflex

The plate deployed by Multiflex is the ITP-60 photopolymer plates which is supplied to VeePee Graphics who in turn supplies the processed plates to Multiflex who produce multilayer flexible packaging. They have been using the ITP-60 photopolymer plates for two years

07 Nov 2023 | By Ramu Ramanathan

It all began when Bengaluru headquartered VeePee Graphics conducted fingerprinting and profiling before the commencement of printing. As per Prasenjit Das who is senior cluster manager at Macdermid, "ITP-60 is best suitable for any kind of screening technologies as it can reproduce the best possible results."

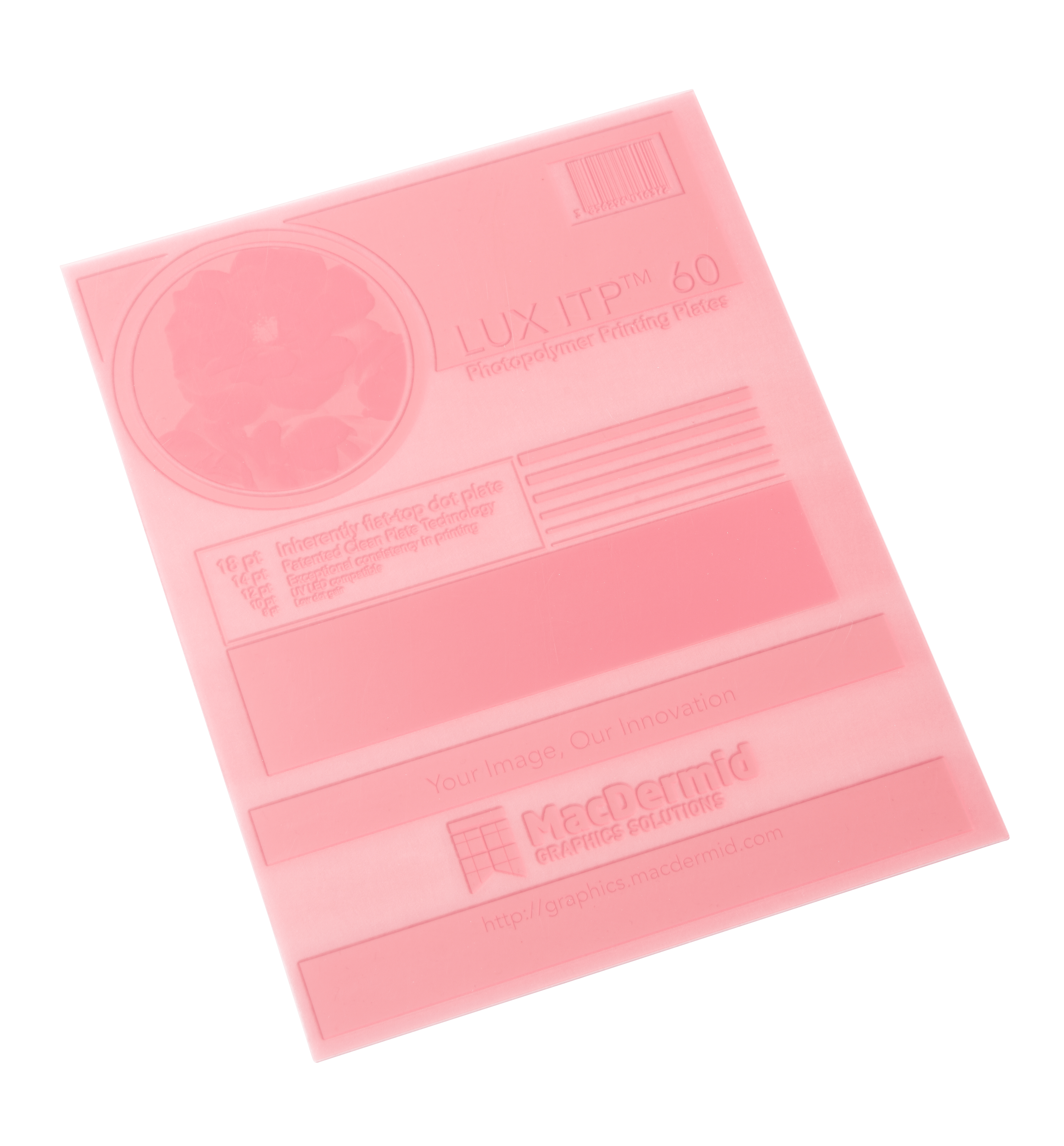

Das says, "The premier Lux ITP plate product is Lux ITP 60, a hard durometer plate formulated with award-winning technology from MacDermid. The Lux ITP features the convenience of flat-top dots right out of the box. No additional platemaking steps or equipment are needed to create a flat top dot on the plate. The advantage for using ITP-60 is the print quality and consistency it provides." The Lux ITP 60 is a 78 (Shore A) durometer plate that offers near 1:1 imaging capability, helping the printers to print extended colour gamut and hold smaller dots.

As per Das, "The Lux ITP 60 is a durable and extremely low tack plate, which is perfectly suited for long and clean running print jobs. It is designed to be processed in either solvent or Lava thermal systems.” Das adds, “ITP-60 plate is compatible with UV LED exposure devices.”

When Rajendra Mehta of Multiflex showcased some samples to the WhatPackaging? team, we asked what method does a converter have to apply for white ink laydown? Das told us, "The ITP-60 plate + proper screening technology helps in achieving a good white ink layout."

Likewise when we asked since anilox rollers are made of chrome and ceramic. How do the tech operators at Multiflex metres ink onto a Macdermid plate? Das replied, "Mostly ceramic aniloxes are used. Quantity of the ink on the plate depends on its volume of the cell in the anilox measured as lines per inch (LPI) or lines per cm (LPCM). Bigger the volume, more ink is transferred to the plate thus to the substrate."

Providing insights about doctor blades, Das says, "There are two types of doctor blades, and both are essential in flexo printing: Metering doctor blades: remove excess ink from the smooth, non-engraved parts of the anilox roll. Containing doctor blades: prevents ink from running out of the flexo chamber and prevents pollution of the ink."

One of the keys to good flexo printing, according to Das, is proper profiling of the press. He says, “Once proper profiling is done, we can get the desired results consistently.”

Das says, “The introduction of computer-to-plate technology, digitalisation, colour correction software, automation engines and last but not the least - improvement of photopolymer plate technology both with thermal and solvent workflow has simplified the platemaking process to a large extent.”

Today, MacDermid has a fully equipped supply chain in India where plates are stored in multiple warehouses. Das says, “Once we receive customer orders from the customer we are capable of delivering the material in 48-72 hours."