Ripe for a turnaround: Jak charts a new course

Mumbai-based Jak Printers, known for their high-quality book printing, has embarked on a journey of transformation—shifting its focus towards the fast-growing packaging industry. Heralding this change and transition is Zeenia K Patel, director of operations, Jak Printers.

04 Feb 2025 | By Sai Deepthi P

Before taking the book printing industry by storm, Khushru Patel and Aspi Forbes used to produce labels for Bournvita. Now, as Jak Printers steps into the world of packaging, Zeenia K Patel, the brain behind the makeover for Parsi Dairy Farm, smiles at the journey’s full-circle moment.

The transition for Jak towards packaging was "natural and not forced in any way," says Zeenia. Therefore, it was not an overnight decision but rather a natural progression in response to the industry demands. As consumer preferences evolved, so did the company's ambitions. "The first run is always the longest," Zeenia says. "But once we overcome initial challenges, subsequent runs become much smoother and more cost-effective. Each time, we learn something new—how to save time, reduce costs, or improve efficiency."

The rise of quick commerce has reshaped packaging needs. Packaging now dominates the psyche of younger generations, and the expectations are relentless. “Gifting the same design twice? Unthinkable,” Zeenia laughs. Brands now undergo frequent reboot to stay relevant.

The learning curve

One of the key challenges Jak Printers encountered was a steep learning curve. It required the ability to adapt to an entirely unique set of production requirements. Unlike book printing, which requires revisions post-completion, packaging involves constant iterations which are based on trends and feedback. “Transitioning from decades in book printing to packaging, we are steadily navigating the technicalities of the process,” says Zeenia.

However, delivering quality products remains an uncompromised promise at Jak. "We are very particular about what leaves our factory. Our customers choose us for the quality and trust we deliver," she says. For example, Jak Printers transformed Bombay Sweet Shop’s packaging by introducing gold-embossed boxes, which became an iconic signature for the brand. They never returned to their original blue design.

Zeenia admits, "We have only been involved in packaging for the last seven years. And two of those years were during the Covid months, which presented its own set of difficulties. There's still a lot to learn."

Right time is now – Parsi Dairy Farm rebranding

Zeenia’s leadership has not only positioned Jak Printers as a serious contender in the packaging space but has also played a role in reinvigorating Parsi Dairy Farm, 100-year-old family-owned legacy brand, through a packaging revamp. “It was always a question of when and never a question of how,” she recalls when asked about the inspiration behind the makeover.

Balancing legacy with modernity, she chose to retain the brand’s iconic stripes but expanded its colour palette to pink, light-blue hues, bold strokes of gold, orange, and green. The aim was to preserve the brand’s iconic nature while adapting to appeal to the younger generation. Like dairy, it needs to stay fresh. When asked why the packaging was not outsourced, Zeenia says, “Outsourcing wasn’t an option. If it bears our name, it must reflect our standards.” The response has been most rewarding.

Down to the details

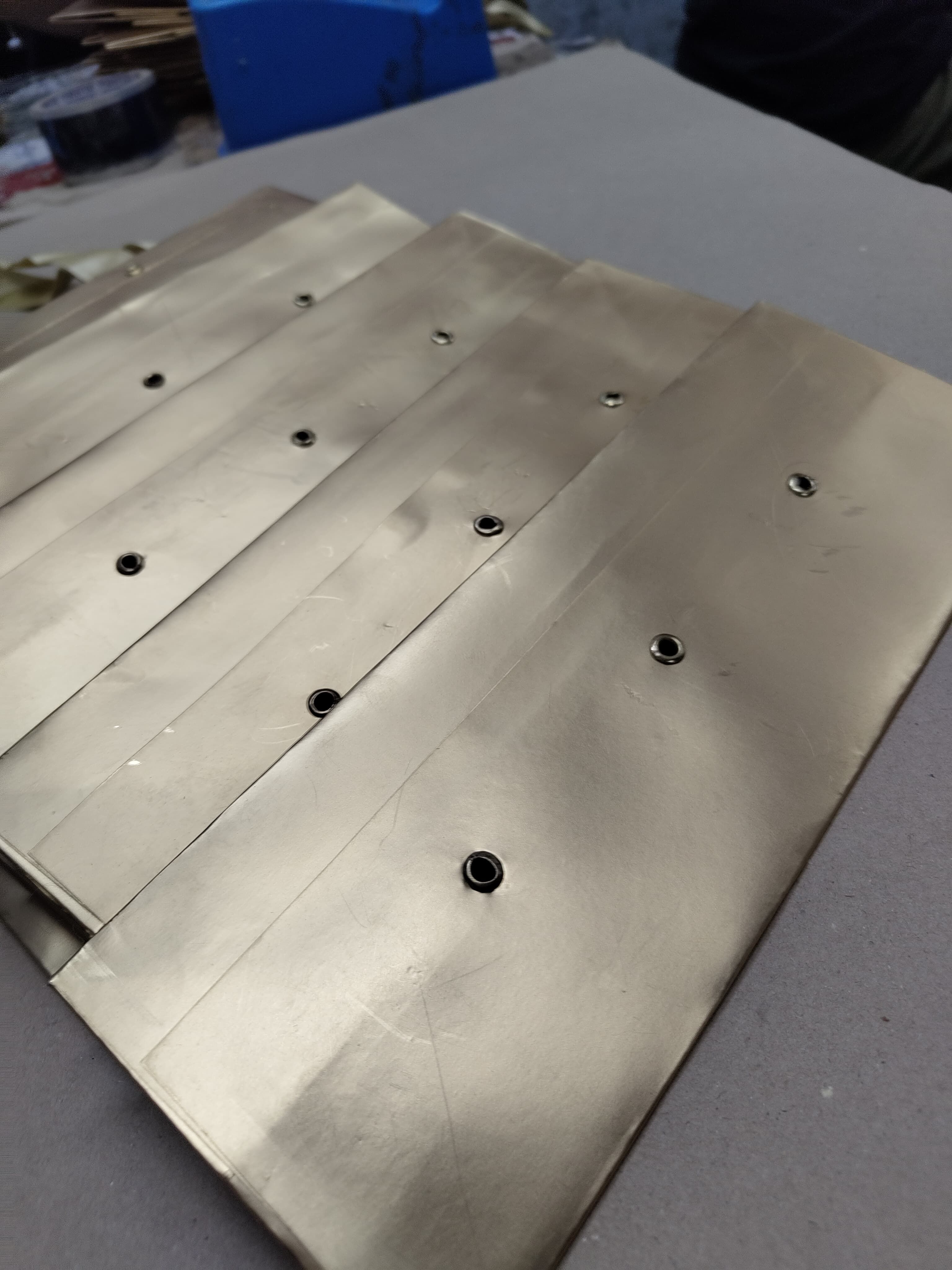

The rebrand introduced hot foil stamping on varied boards for a premium feel, leveraging Jak’s expertise to develop intricate, high-end packaging solutions. Jak Printers wants to deliver a complete experience—necessity in an era where unboxing videos reign. Even Parsi Dairy Farm’s ghee bags feature eyelets at the bottom of the bag for solidity and stability.

They have also made a conscious effort to reduce and limit plastic in their packaging. Most of their products use plant-based packaging, right down to the carry bags—a costly but conscious choice. Today, she says, the key is to unfold packaging ideas that cut carbon footprint.

While Jak Printers champions eco-conscious materials, Zeenia admits that recycled paper costs 30–40% more than virgin paperboard. “Even eco-aware clients prefer cheaper options,” she explains. She remains hopeful that policy changes and market shifts will make sustainable packaging more accessible.

Despite the challenges, Zeenia finds satisfaction in the journey. "Seeing our packaging out in the world, whether it’s a friend spotting Parsi Dairy Farm’s new look in a supermarket or a client reordering boxes because they’ve sold out, is incredibly rewarding."

The big picture

Jak Printers’ story mirrors the packaging industry’s evolution, which requires a blend of tradition and technology, the right balance between sustainability and functionality, and a knack for always staying ahead of the curve, always.

With the rise of e-commerce and quick-commerce models, Zeenia sees massive potential in the sector. "In traditional retail, a single box might serve multiple purposes. But when products move online, packaging needs to be more specialised—each item requires its own protective yet appealing packaging. This means the demand for innovative packaging solutions is only going to grow." She believes that staying on top of technological advancements is key to maintaining a competitive edge.

As I exit the oasis that is Jak’s factory in Byculla, one thing is clear, Jak has pushed the agenda of packaging designs to newer levels of brilliance. Be it: Subko chocolates or Parsi Dairy Farm; Jak has made a mark. There is functionality, there are developments in materials and techniques that allow for ever-more unusual pieces. Above all, there is style.