Project recycling: What really happens to 15-kg edible oil cans

The second-hand tin segment is hazardous. Cleaning edible oil tin cans means menial, unlawful and hazardous jobs. In two months, a dedicated team at JSW Steel transformed the waagris from obscurity to becoming partners. A report by Ramu Ramanathan

16 Aug 2023 | 3624 Views | By Ramu Ramanathan

It was a presentation during the Respack conference on 8 and 9 June, sandwiched between a host of similar presentations. But the JSW Steel team made the Respack delegates sit up. The presentation pointed out, "Within various states, several clusters re-used more than a lakh of tins per month. Each cluster has a few large and several small units involved in the cleaning and caters to re-packers located within a 25-30km radius who pack and sell blended oil under their brand names."

The case-study was about a JSW pilot study in Pune. How the team reached out to re-use tin cleaners and dealers and replicated the model, right from identification to engagement to onboarding, as well as providing an innovative financing solution.

When I asked how this is important, the JSW team alluded to the tinplate consumption data of India, which is 700-lakh tonnes. Of this, 38-40% is consumed by the edible oil industry for its 15-kg bulk pack segment. This segment is driven by the hotels, restaurants and catering (HoReCa) industry. The super-brands like Adani Wilmar, Patanjali, Cargill, Bunge, and Gemini have found their way to fine dining and five-star hotels. The rest of the small and mid-level roadside eateries, are serviced by the re-use tin market.

The numbers are staggering, and the re-use tin market caters to the bulk of the population. In a way, that's how the JSW Steel mission began.

A preliminary field report revealed a huge potential to transform India's edible oil bulk packaging industry. As the JSW spokesperson says, "Coupled with the support of a highly committed leadership at JSW, the sales team began an unprecedented and historic mission to reach out to the major second-hand tin cleaners across every state and cluster." The JSW team engaged with them and convinced them to stop cleaning and instead crush the used tins to be sold to JSW as scrap.

A task that looked simple. But as they say in India, that nothing is easy till it is done.

To begin at the beginning

How did the journey, start?

For this, let's flashback to 28 February 2023. A quiet auditorium. The plush headquarters of JSW Centre. Gentle, quiet conversations. A gathering of JSW's discerning customers. Most of them were waiting. And then he walked in. The doyen of the steel industry: Sajjan Jindal.

It was a customer meet organised at the JSW headquarters where the Man of Steel wanted to touch base with the customers. He was keen to get their feedback about the tinplate business. Sajjan Jindal wanted to hear from the customers as to how we could work together to increase the consumption of tinplate – proven for its 100% recyclable packaging - in India. On cue, ideas and inputs and information flowed.

As the interactions began, a leading edible oil customer based in Hyderabad, expressed concern about a serious problem plaguing the edible oil industry. "Sir, the edible oil industry is being severely impacted by re-using the 15-kg edible oil tins". Others in the room echoed this sentiment. They expressed their concern over the rampant use of re-used tins. Not only was it unlawful and a serious health hazard, but there was also the duplication problem.

Jindal probed further in order to understand the scenario and grasp the ground realities. Just then, a lady who was related to the tinplate business stood up and made a suggestion. "Mr Jindal, why can't you buy back your cans?" The suggestion hit the right chord with the managing director of JSW Steel. There seemed to be a lot of merit in this seemingly innocuous comment. And so, after some brain-storming, a feasible solution was sought.

One can crush these used cans at the point of collection and buy it back. As a responsible corporate citizen, Jindal took this as a personal mission and corporate responsibility to address the concerns. Later in the day (that's right, the same 28 February), he advised his leadership team to work on the project and come back with a clear execution plan which kept "the best interest of all the agencies involved in the process."

The JSW Steel sales team swung into action and began combing the country cluster-by-cluster. Thus began Mission 15-kg Edible Oil Tins.

A tall task: How to transform re-use tin cleaner clusters

Mission 15kg Edible Oil Tins

The JSW Steel team collated data to understand the eco re-use tin industry eco-system. It entailed multiple visits and interviews with the agencies involved. Initially, there was resistance, lots of resistance. But the big picture revealed itself.

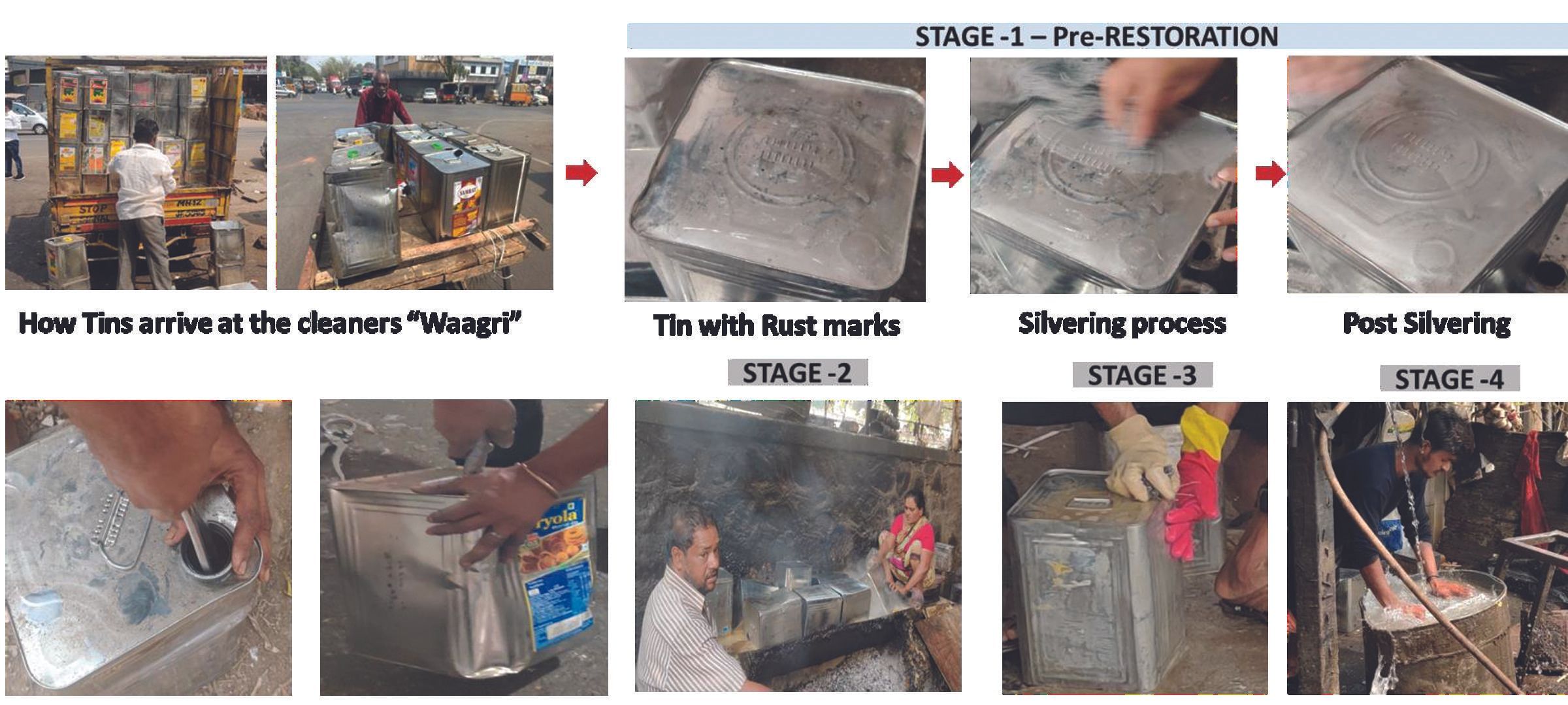

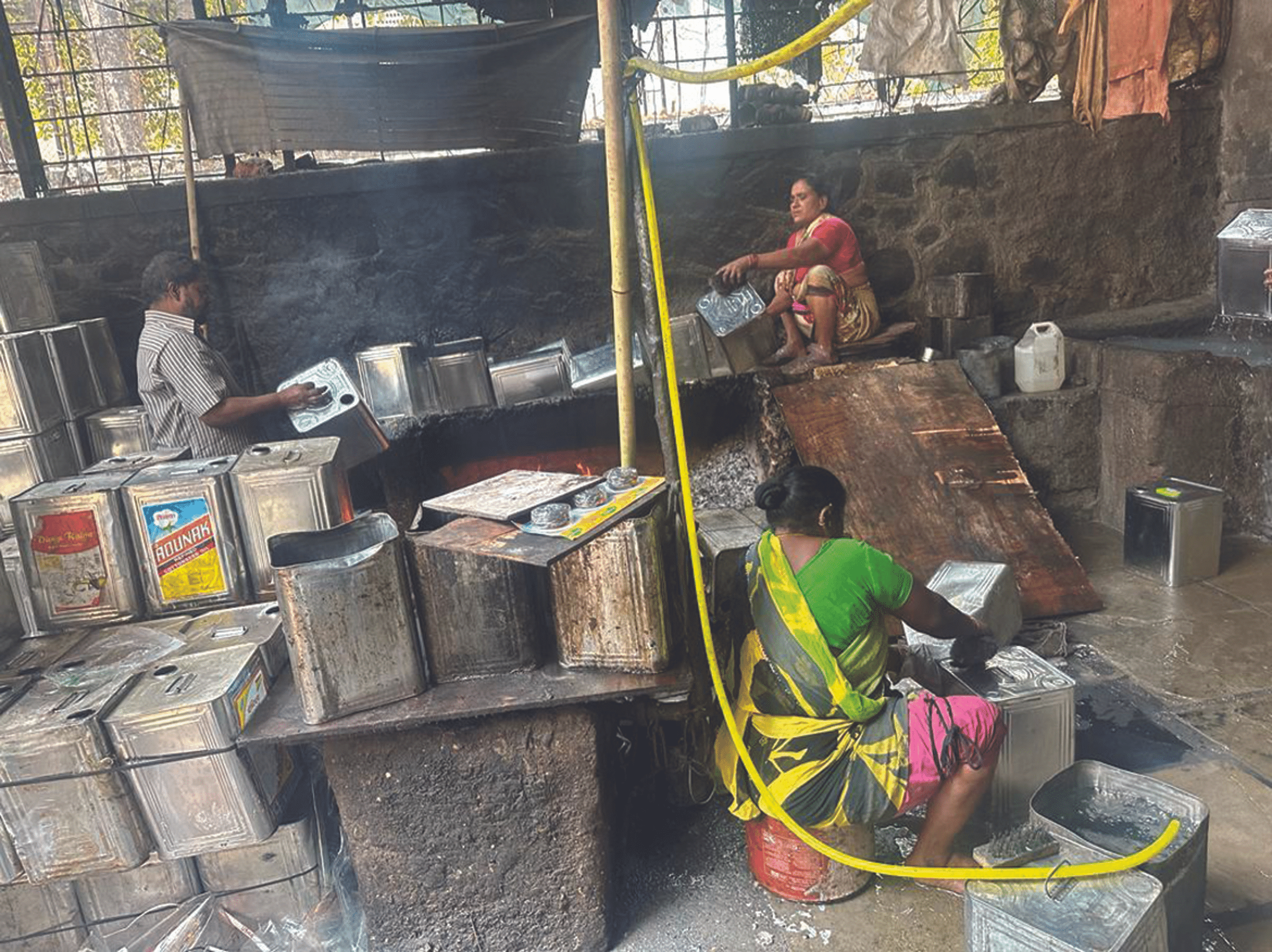

One of the things WhatPackaging? magazine noticed while talking to industry experts is, the re-use tin industry is a very well-entrenched system which involves several below poverty line (BPL) families whose livelihood was dependent on this business. An average of 6-10 workers were involved in the process; most belonged to the same or extended family.

The task is massive. For starts, within each state, several clusters re-used more than a lakh tins per month. Each cluster has a few large and several small units involved in the cleaning and caters to re-packers, located within a 25-30km radius, who pack and sell blended oil under their own brand names.

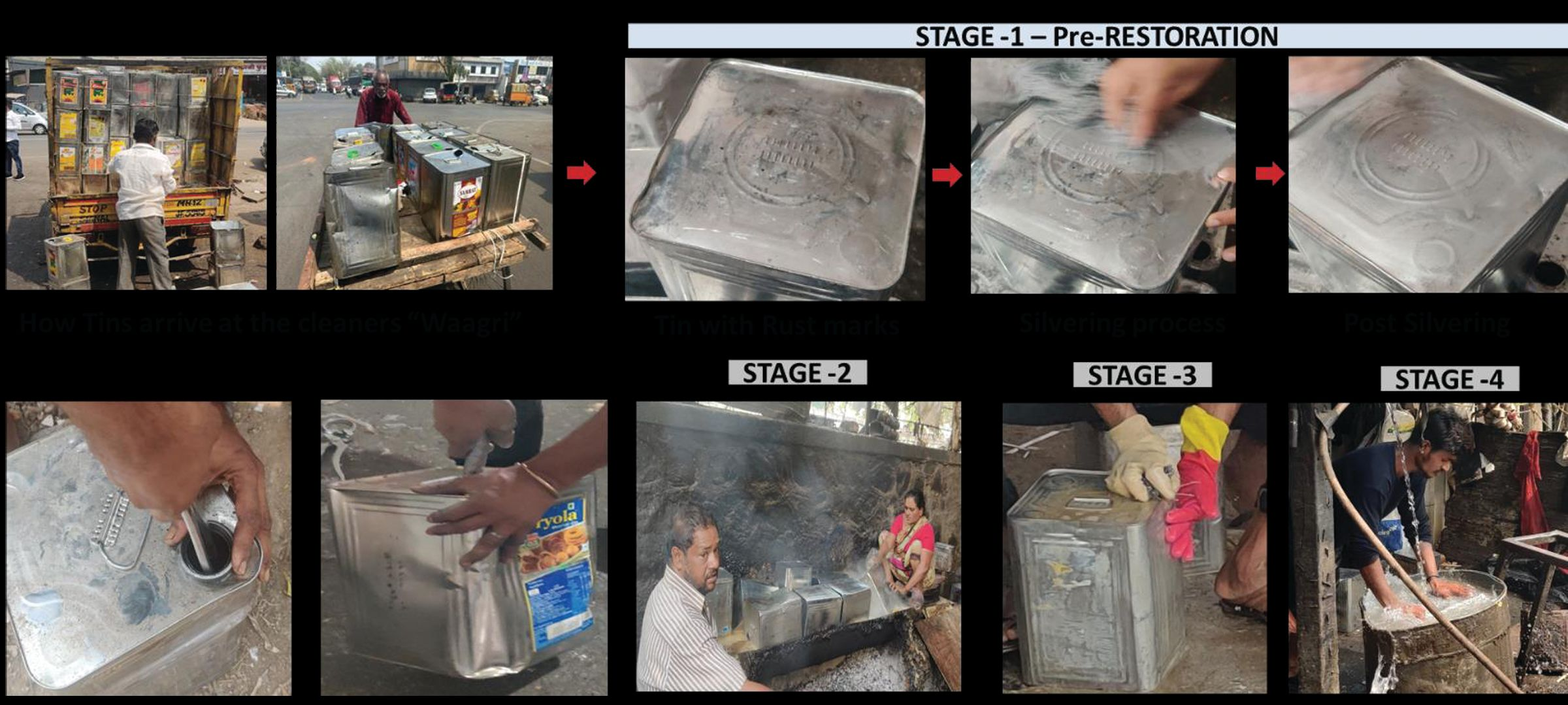

The most shocking discovery that emerged was when the team managed to visit some of the units where the cleaning was being done. The process (please refer to the illustration) was rendered in the most unhygienic manner with total disregard to the nature of the content being handled.

First, the tins are physically restored to fix the spout, remove rust marks, and dents, and then washed in a bath that comprises boiling water, caustic soda and detergent. The cleaned tins that are "apparently ready" for re-sale to repackers are most likely to have remnants of the cleaning agents, making it dangerous for further oil-filling and consumption.

Two things that emerged very clearly were that the people involved in the actual collecting (pheriwallas) and cleaning (waagris) process were from the lowest strata of the society. They had no alternate source of income or the education or skill sets for doing anything else.

The second aspect from the consumers’ perspective was even more serious, as almost the entire oil packed in this dangerously unhygienic manner was being supplied to hotels, restaurants, dhabas, street and food vendors. Millionsof Indian consume food at these hubs.

The point is, India is dealing with a serious health hazard and a silent killer. The question was: how can one intervene and change the process without hurting an entire community’s livelihood?

Working together: The recycling communuity and team JSW

The pilot project

The preliminary field report revealed a huge potential to transform the country's edible oil bulk packaging industry. It meant, as the JSW team shared with WhatPackaging? magazine, support from "a highly committed leadership at JSW". The sales team began an unprecedented and historic mission to reach out to the secondhand tin cleaners.

The plan was simple: Brief them, request them to cease cleaning, and crush the used tins to be sold to JSW as scrap.

Hoc est simplicismuss? No, not at all.

In order to test the model, the JSW team decided to target a specific market for the pilot study: Pune.

The process was, two leading re-use tin cleaners were identified and approached. These cleaners had the facility to crush the tins into bales, plus they were located close to the Dolvi unit where the scrap would eventually go and hence were ideal for the pilot study. It took the team several visits, meetings and the full support of the Pune-based prime customers to explain the proposal to the cleaners.

The JSW team had to grapple with a lot of resistance, suspicion and reluctance. Finally, the plan and the long-term advantages it entailed were explained.

There was a lot of assurance to ensure each and every member's interest would be protected. And no one was hurt, and no one's livelihood was affected.

JSW Steel placed two of the team members on-site to monitor and support the process. KYC documents were collected, and SAP codes were created as they were formally onboarded as JSW Steel vendors. Within two weeks, the first truckload of baled tin scrap was ready to be despatched to JSW Steel's Dolvi unit. All agencies involved were paid on time, and the complete process was tested from end-to-end.

A simple but massive transformation

After the success of the pilot study, there was no turning back. The team reached out to similar re-use tin cleaners and dealers in several other states and clusters. It replicated the entire model - right from identification to engagement to onboarding. JSW also provided an innovative financing solution through Tata Capital to help vendors fund the baling machines.

In addition, JSW opted for a reverse factoring agreement with Tata Capital to ensure speedy payments to vendors to support the tin cleaners as they migrate from the cash system to digital payments.

The JSW spokesperson told WhatPackaging? magazine, "The result of this multi-pronged approach was all the progress we achieved was in two months. It speaks volumes of the team's dedication and commitment to the cause."

The journey was challenging. JSW was attempting to disrupt a well-entrenched system, operating for generations. The positive factor was the alternate and equally, if not more, profitable solution JSW offered, coupled with the fact that both the cleaner community and the re-packers needed to be more comfortable with the existing re-use system.

What’s the advantage?

A host of issues like damages, leakages, and fear of raids by officials loomed over them. Therefore, an innovative business model from a large reliable organisation was a proposal worth trying, and that’s what largely helped us crack this. Merely trying to go and trying to put a stop to this without offering any alternate way out would have surely failed. In monetary terms, tin scrap is significantly pricier than regular melting scrap, but still, as a commitment to society and to set an example of demonstrative leadership, JSW is absorbing this cost.

Future plans: What next ...

Presently, JSW is committed to scaling this sustainably. The plan is to onboard at least 50-60 vendors and collection centres. The target is: to scrap at least 35,000-40,000-MT in 2023.

A statement from JSW says, "The group is developing a digital platform for this business to manage everything with just a touch of the finger."

As an industry leader, JSW has led in embarking on a transformational and revolutionary initiative. However, to make this successful and sustainable, we need the support of the entire value chain, including government authorities like the FSSAI, Metal Can Manufacturers Association (MCMA), Indian Tinplate Manufacturers Association (ITMA), and edible oil manufacturers associations.

As a body, the industry could conduct this in an organised manner and publish the data. Thereby, both the GoI and civil society will be made aware. Plus, it will enhance the environment and health consciousness among consumers.

Meanwhile the work continues ...

Recyclers supporting the initiave

We promise to support JSW fully, say recyclers

|

My family and I are very grateful to JSW for this excellent initiative. As president of the Second-Hand Tin Washers Association, I have told everyone to stop washing old tins and work only on crushing. This is a more respectful job than cleaning. We promise to support JSW fully and ensure the project is implemented in Gujarat. Arif Memon, |

Honoured to be a part of the sustainability vision and initiative JSW Steel took. Running a machine at full capacity makes us proud. Initially, it involved a lot of difficulties pertaining to procurement, supply chain and trainings. The support we've received from JSW is immense. This initiative is bigger than all of us. We will continue to be a part of it. Surendra Agarwal, |

It is a whole new experience for the team on this project. We can proudly say that this project is providing employment to 42 godowns in New Delhi and approximately 840 peddlers who are collecting empty 15kg tins from shops and households. On the other hand, this project will improve the quality of oil provided to the consumer as there will be no availability of old tins for the re-packers in the market. Kishan and Prateek Dhingra, New Delhi. |