Product Watch: Flint Group’s Vivo Colour Solutions software endorsed by Pragati and Skanem

Flint Group’s Vivo Colour Solutions has seen successful implementation among narrow web converters in India. According to Flint Group India, Vivo has been installed at Pragati Pack in Hyderabad and Skanem India across three locations. Additionally, a new contract has been signed with Alpine Container in Jammu. With this partnership, Vivo will be implemented at five locations in India

08 Dec 2023 | By Aditya Ghosalkar

The Vivo endorsement is solid. Hemanth Paruchuri, the director of Pragati Pack India, says, “Vivo has been an invaluable tool in reducing the time and iterations required to match the ink to the required Pantone shades.” Hyderabad-based Paruchuri adds, “The software takes into account the different variables that we experience every day, such as different aniloxes with varying volumes and the substrate on which the printing is being done.”

Sujesh Pandalangat, the director of operations at Skanem India who has been using the Vivo software provided by the Flint Group since November 2022 across all Skanem plants in India says, “It has been instrumental in achieving accuracy and consistency in shade matching while also increasing press uptime and reducing substrate wastage.” Pandalangat adds, “Our investment in Vivo technology has propelled Skanem forward in our digitalisation journey. Gone are the days of wasting press time on shade-matching trials and relying solely on human skills. With Vivo, we can consistently deliver high-quality colour to our customers.”

When WhatPackaging? magazine spoke to the spokesperson at Flint Group, we were told, “Flint Group understands that packaging colour and design consistency are paramount to building globally recognised brands. Also, we have a fundamental understanding of the challenges both brand owners and printers have in tackling colour management across jobs, presses and sites. Colour management is about delivering the impact, consistency and reliability of print that brands are seeking, it’s also about driving important efficiency and sustainability into the print operation itself.”

So what does the Vivo software do?

It delivers continuous improvement in colour management. This means printers by default are eradicating waste, reducing lead times and meeting environmental impact objectives. The print firms are delivering the right first-time production avoids unnecessary use of materials, minimises energy and creates speed to market improving customer satisfaction: a win-win for all key stakeholders. The key to resolving the challenge is to have a comprehensive colour management programme that integrates with the overall packaging print workflow.

In the packaging industry, it is common to employ special and Pantone shades to boost brand recognition. Most brands place significant emphasis on reproducing these shades in their packaging materials. However, when attempting to replicate such shades on a flexo press, various variables like anilox selection, press conditions, plate types, and more can pose challenges in achieving precise shade reproduction, whether on the same press or across different presses.

According to Flint Group, “Many converters expend considerable time and costly resources on colour matching before a job gains approval from the brands. Due to inadequate training and setup, operators at these converters find themselves matching shades on the press, which causes a bottleneck plus uses valuable resources in shade matching and diminishes overall productivity.”

With Vivo Colour Solutions, Flint Group aims to empower converters to achieve accurate reproductions of special shades right from the start, enabling them to proceed directly to the press for printing. This approach enhances productivity through the efficient utilisation of resources.

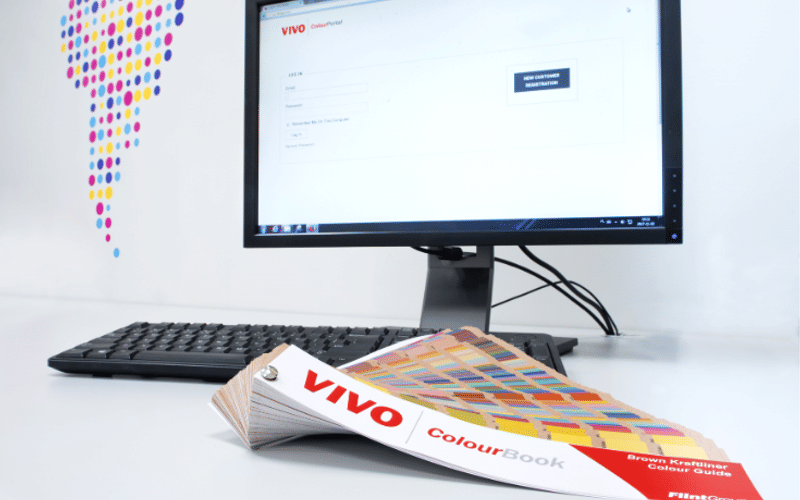

The Vivo Colour Solutions comprises many modules. These include Vivo ColourCloud and Vivo ColourPortal. The Vivo ColourCloud serves as a comprehensive database containing Pantone shades and their accompanying recipes across various anilox and substrate combinations. Meanwhile, Vivo ColourPortal provides a mechanism for requesting specific shades and recipes based on unique printing conditions and Lab values. Flint Group’s Global Colour Centre in Poland is responsible for the creation of recipes for the cloud or via the portal.

The implementation of Vivo follows a press audit ensuring that the recipes provided by the system are customised to suit the specific printing environment. This process takes into consideration factors such as press conditions, plate usage, pressure settings, anilox library and more.