Product Watch: Corob’s Nova+ gravimetric dispenser

The Nova+ gravimetric dispenser recently won a SIES SOP Star Award and was recognised for excellence in packaging. Dipankar B elaborates on the product.

13 Mar 2025 | By WhatPackaging? Team

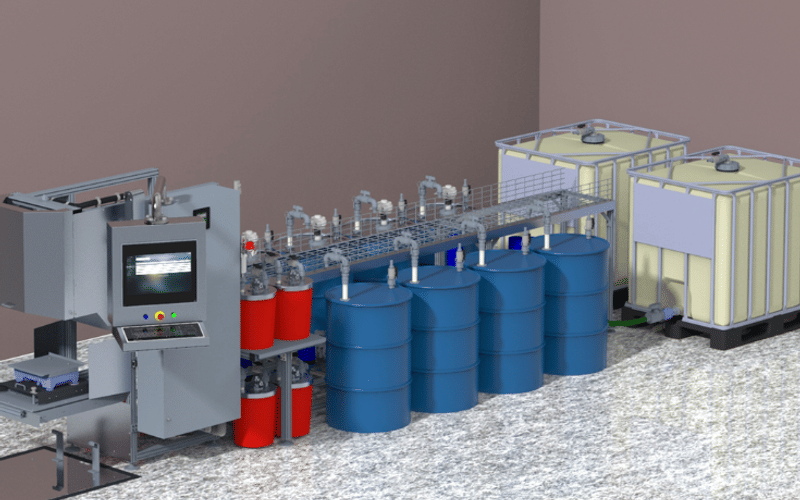

The Nova+ gravimetric dispenser is designed to handle a variety of materials, including liquids and pastes. It is suited for dispensing inks, paints, and other similar substances. The system's gravimetric dispensing technology is ideal for the printing, packaging, and paint manufacturing industries.

The Nova+ ink dispenser can dispense materials with an accuracy of up to 0.1 to 0.2-grammes using multistage valves. The dispense range varies from 0.16 - 170-litres per minute with a scale capacity of 15–3000-kilogrammes, depending on the specific configuration and requirements of the application. This flexibility makes it suitable for both small-batch production and large-scale industrial applications.

The system uses specialised software and hardware components like multistage valves to manage the dispensing process. This includes features like adjustable flow rates, automated calibration, and real-time monitoring. Being a closed loop circuit, it also gets real-time feedback from the scale in terms of actual versus target dispensed quantity and hence controls the valve opening to ensure a consistent result.

The Nova+ ink dispenser can be integrated with existing production lines. The system is designed with flexibility, allowing it to be customised and adapted to various production environments. It can be integrated into both in-plant and on-demand production setups. This includes features like cloud database connectivity, real-time monitoring, automated calibration, integration with spectrophotometers, and ERP integration, which helps ensure consistent performance and easy integration. The same can be operated and accessed remotely through TeamViewer and can generate reports such as trend analysis and inventory management.

The system's resolution can be tuned from 0.1 to 0.2 grammes on request, enabling it to measure very small increments in weight accurately. The system's sensitivity is designed to detect even minor weight changes, ensuring that the dispensing process is extremely precise and consistent.

The dispensing speed and cycle time of the Nova+ ink dispenser can vary depending on the specific configuration and rheological properties of the materials and the number of components in a single recipe. However, the system can handle both small and large batch sizes.

The Nova+ ink dispenser offers remote monitoring with preinstalled software in the machine and control capabilities. It handles data logging and traceability through advanced software solutions such as data logging, traceability, software integration and automated record-keeping.

The lifespan of the Nova+ ink dispenser system can vary depending on usage, maintenance, and operating conditions. However, with proper maintenance and regular servicing, the system is designed to provide reliable performance for many years. Typically, such industrial dispensing systems can last anywhere from eight to 10 years, or longer if well-maintained.