Pack8: dedicated to a plastic-free, automation-first packaging ecosystem

Praveen Shinde has been at the forefront of creating eco-friendly, high-performance solutions that deliver real value to businesses while staying kind to the planet. Charmiane Alexander speaks to Praveen Shinde about Pack8's vision "to eliminate plastic from transit packaging while ensuring automation-driven efficiency."

11 Feb 2025 | By Charmiane Alexander

Pack8 has been in the news ever since it was named among the Top 10 Packaging Startups in India (2021) by Industry Outlook Magazine and won the MSME Golden Business Excellence Award 2023 for Sustainable Packaging. Since then, Pack8 has been setting new benchmarks, proving that doing what’s right for the environment can also mean doing what’s right for business.

Praveen Shinde says, "We recognised early on that businesses needed sustainable packaging solutions that didn’t compromise on protection or cost-effectiveness. Over the years, we’ve built a strong foundation with in-house manufacturing, deep customer insights, and a commitment to innovation, allowing us to scale without losing sight of our core mission.

Today, Pack8 operates as a 100% Indian startup with in-house production. The primary manufacturing facility is in Navi Mumbai, and the group has corporate offices in Delhi and Bengaluru. Internationally, Pack8 has subsidiaries in London and an upcoming one in Dubai.

Shinde says, "We focus on automation-first packaging, ensuring businesses can scale without adding complexity. He says, India has a great potential to offer sustainable and eco-friendly alternatives. He tells WhatPackaging? that "India has a rich heritage of frugality and sustainability. Our access to raw materials like Kraft paper, combined with advancements in local manufacturing and automation, positions us uniquely in the global packaging ecosystem."

He adds, "More importantly, Indian manufacturers are increasingly adopting closed-loop supply chains, ensuring minimal waste while maintaining cost efficiency. With global brands looking to reduce their carbon footprint, Indian packaging solutions are an obvious choice."

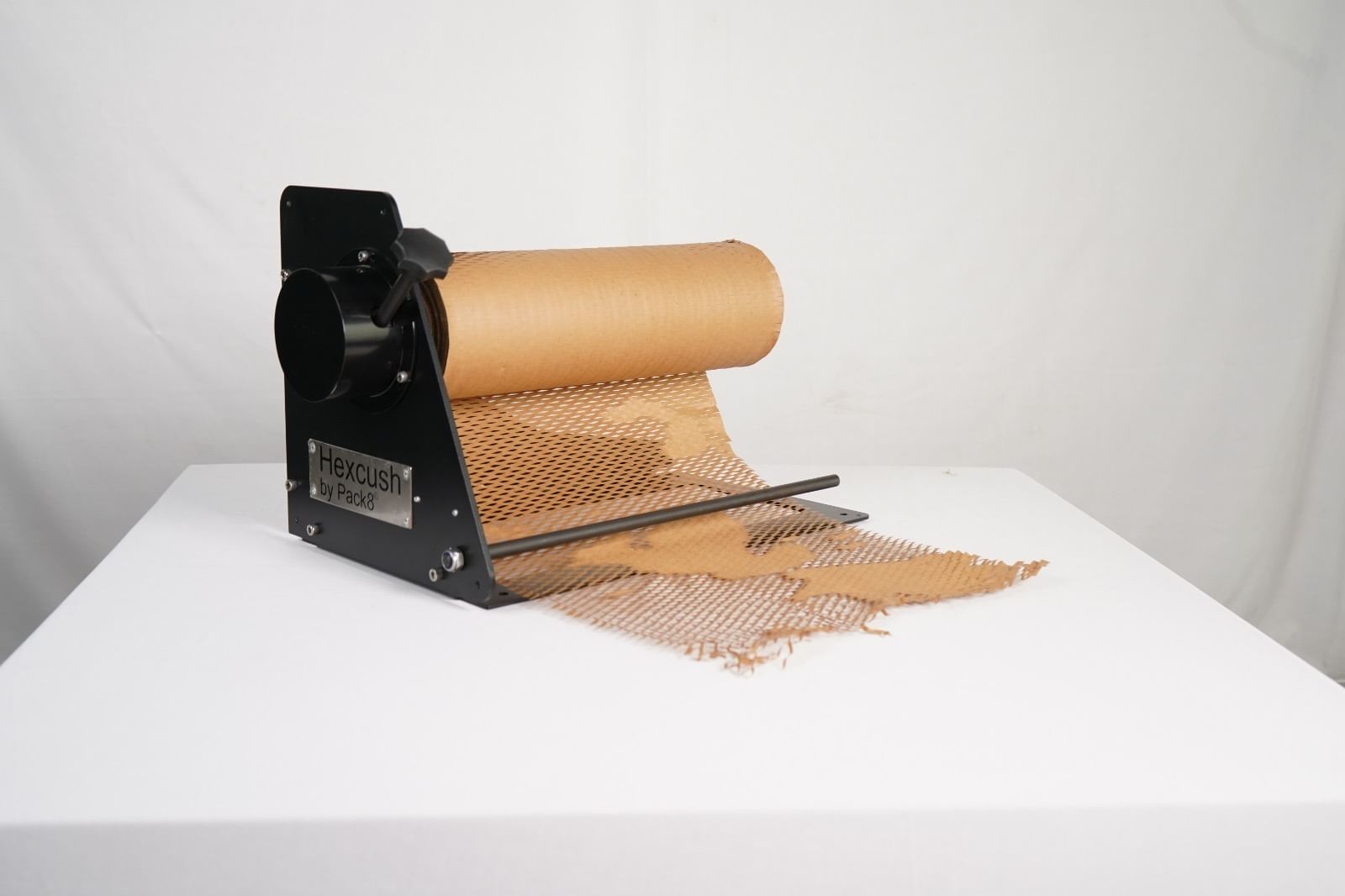

The Pack8 product range includes HexCush which is a paper-based alternative to bubble wrap; Void Fillers which is a sustainable option to protect shipments; Cushioning Solutions which is a shock-absorbing paper wrap; Paper-Based Mailers & Bags which is a plastic-free shipping solution; and Tamper-Proof Paper Tapes which is a secure and eco-friendly sealing option.

HexCush is a paper-based alternative to bubble wrap

How HexCush fulfills its role as a paper-based void-filling solution

Praveen Shinde says, "HexCush is a honeycomb-structured paper wrap designed to replace plastic-based bubble wrap. It expands upon application, creating an interlocking cushioning effect that absorbs shocks and prevents damage during transit." Unlike plastic, HexCush is 100% biodegradable, compostable, and recyclable, making it a perfect solution for businesses aiming for sustainability.

HexCush comes in various sizes and GSM options based on the specific use case. The GSM variants are: 60, 80, and 100 GSM, depending on the required strength. The roll dimensions are typically 500mm width and lengths ranging from 50m to 250m. Praveen Shinde says, "The costing varies on bulk orders, but it is designed to be cost-competitive with bubble wrap as far as efficiency and material wastage are considered."

Shinde says, the consumption efficiency for HexCush expands when stretched, ensuring 20-30% material savings compared to traditional wrapping materials.

The manufacturing process for HexCush is driven by automation and precision cutting. In addition, the Pack8 team sources FSC-certified Kraft paper which is used to ensure sustainability. In addition, cutting and perforation ensures the paper is cut in a precise hexagonal pattern for expansion.

Plus there is rolling and packing which ensures the perforated paper is rolled for easy dispensing and use. Shinde says, "The quality check is stringent and each roll undergoes strength and expansion testing before dispatch."

HexCush is designed for diverse industries, including: eCommerce brands for shipping clothing, accessories, and fragile goods; plus food packaging for safe direct contact and ideal for bakery and pizza box inserts. Also there is home and lifestyle which is used by brands selling ceramics, glassware, and décor. And finally there is automotive and electronics which is ideal for lightweight yet shock-resistant protection.

Shinde: HexCush is cost-effective with minimal material wastage

How Pack8 has gained ground

The most common feedback the team at Pack8 receives is "Why didn’t we switch earlier?". Shinde says, "Customers love the ease of use, branding potential, and sustainability aspect. From a customer’s customer perspective, we’ve heard that unboxing experiences have improved significantly, with many preferring eco-friendly alternatives over plastic-based solutions."

We asked what sets the HexCush apart from similar options in the market. Shinde says, "A few key differentiators are that it is cost-effective because there is lower material wastage as compared to plastic alternatives." Also it is automation-friendly and integrates into existing packaging lines. Shinde states, the HexCush provides better protection and the honeycomb structure absorbs more impact than standard wrapping solutions.

After Pack8 won the MSME Award in 2023, the company has strengthened its sustainability initiatives like expanded FSC-certified product range and increased recycling efforts, plus carbon footprint reduction. Shinde says, "We are investing in optimising our logistics to reduce emissions. Additionally, we are working on a closed-loop packaging system, allowing brands to reuse materials efficiently." He signs off, "Today sustainability is not just a responsibility but a business imperative."

Praveen Shinde: Four tips for designers

Packaging is often over-engineered—too many layers, unnecessary plastic, and excess use of materials. Our advice for designers:

- Use minimal material – Optimise strength without excessive layers.

- Prioritise Sustainability – Choose recyclable or compostable materials.

- Design for Automation – Ensure packaging integrates seamlessly into packing lines.

- Focus on functionality – Avoid gimmicks; the goal is protection and efficiency.