Good news: Converters and brand owners moving in right direction

DIC-Sun Chemical is at the forefront of innovative coatings solutions across the globe. The global behemoth is supplying coatings for trials and validation. Utsab Choudhuri, chief technology officer and Dr Kamakshi Christopher GM, flexible technology share the highlights with Ramu Ramanathan

08 Aug 2024 | 2618 Views | By Ramu Ramanathan

Ramu Ramanathan (RR): Do coatings offer barrier properties without harmful side effects?

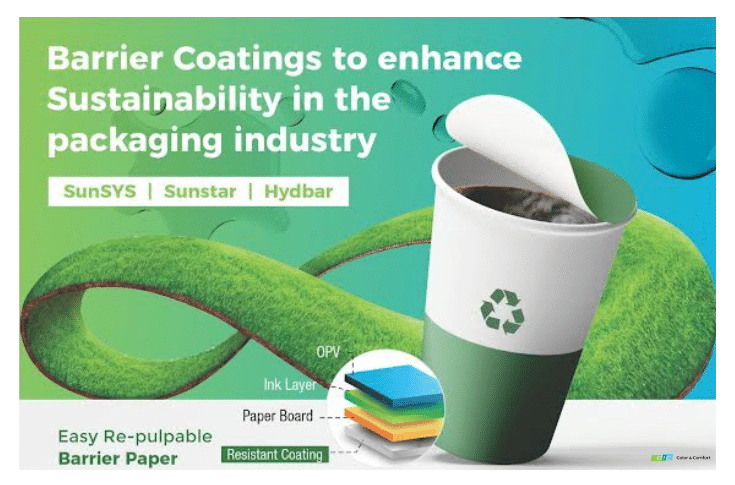

Utsab Choudhuri (UC): High plastic consumption is the bane of the packaging. In this context, coatings offer a route to minimise their use. Barrier coatings are formulated keeping in mind the required regulatory compliance for use.

RR: You have popular products like the barrier adhesive branded as Paslim and the barrier coatings Sunbar. Generally speaking, what is the chemistry of barrier coatings?

UC: The chemistry of the product depends on product performance and compliance requirements. All three categories may be used for different applications.

RR: Is the coating compatible with all methods like gravure, flexo, offset, screen etc.?

UC: DIC-Sun Chemical portfolio of coatings are developed for different methods of application. We see customer requirements through gravure, flexo and offset application methods. Coating techniques depend primarily on chemistry, rheology, and substrate.

RR: What is the minimum gram of coat weight to achieve the desired results?

Kamakshi Christopher (KC): It varies on requirement and substrates. For non-absorbent substrates it is 0.3- 1 GSM - and for absorbent substrates it is 4-7 GSM dry.

The barrier coatings that can be used on gravure, offset and flexo applications

RR: Please share the cost comparison with the normal lamination with chemical coating.

KC: Suffice it to say that it depends on application and end-use.

RR: Ok. But are there any superior benefits? For example, any value addition with a coating that lamination cannot achieve and similar limitations if any. In this sense, what is the right product-market fit for coatings?

KC: One major advantage of using coatings is ease of recyclability which is not the case with lamination. If we compare laminated paper vs coated paper, laminate paper is not repulpable whereas coated paper offers repulpability and reusability. A final cost calculation needs to be arrived at after looking at the whole life cycle. Coating is targeted to have a more sustainable packaging structure for easy recyclability.

RR: What kind of certifications do you have for your product or what certification have you applied for?

UC: Our products are formulated and manufactured as per standard regulatory norms that are globally valid and accepted.

RR: Does it comply with the rules and regulations for the export market?

UC: Our technology is global, and it is approved and has been applied in developed markets.

If we compare laminated paper vs coated paper, laminate paper is not repulpable whereas coated paper offers repulpability and reusability

RR: In terms of sustainability standards, how do your coatings perform on the carbon footprint and recyclability scorecard? Are there differentiated offerings that offer sustainability advantages?

KC: Coatings are a sustainable alternative for replacing multilayer plastic laminate. Multilayer laminates of different polymer families are typically difficult to recycle. Coatings help to build a mono-material type laminate that can be taken up in the recycling stream.

RR: One feedback we have received from Indian converters is that controlling the viscosity of coatings and ensuring consistency is burdensome. Your view?

UC: Well, this can be a challenge in some cases. However, DIC Sun Chemical provides the application expertise, free of charge through its specialised CTS team so that converters can make the best use of the service to plan their trials. Our team will work collaboratively with a converter to ensure the best possible outcomes.

RR: Is there a knowledge gap, or technology gap in the applicator ecosystem that can be addressed? Are there any opportunities to do so?

UC: As this technology is emerging in the Indian market, it is still in a nascent stage. And we believe with time, people will be skilled and they will develop better use of it.

RR: The share of polymers in sustainable food packaging applications is expected to reduce by 50% over the next two decades. Meanwhile, fibre-based materials are projected to contribute to 40% of all materials in use for food packaging. How is this impacting your coating R&D?

KC: Many brand owners and converters are moving towards this direction. However, we have not seen any major shift as of now. We expect it to move after 2025 and our technology is geared for this transition.

DIC-Sun Chemical portfolio of coatings are developed for different methods of application