Flexure hits a landmark 208 LPI with flexo

Ahmedabad-based Flexure Print N Pack has outpaced others by producing high quality print with 208 LPI on CI flexo. Flexure’s director of technology, Jainam Shah talks to Abhay Avadhani about how this record was achieved, and shares insights about how to extract the best out of flexo

22 Apr 2024 | 9602 Views | By Abhay Avadhani

What we know:

Machine and model: Echaar Flexosmart HR 300

Job details: Eight-colour reverse printed; solvent-based inks; solvent-free lamination

Resolution: 208 LPI

Ink: Solvent-based inks

Pre-press provider: Pin Mark Block, Kodak Flexcel NX printing plates; hybrid screening

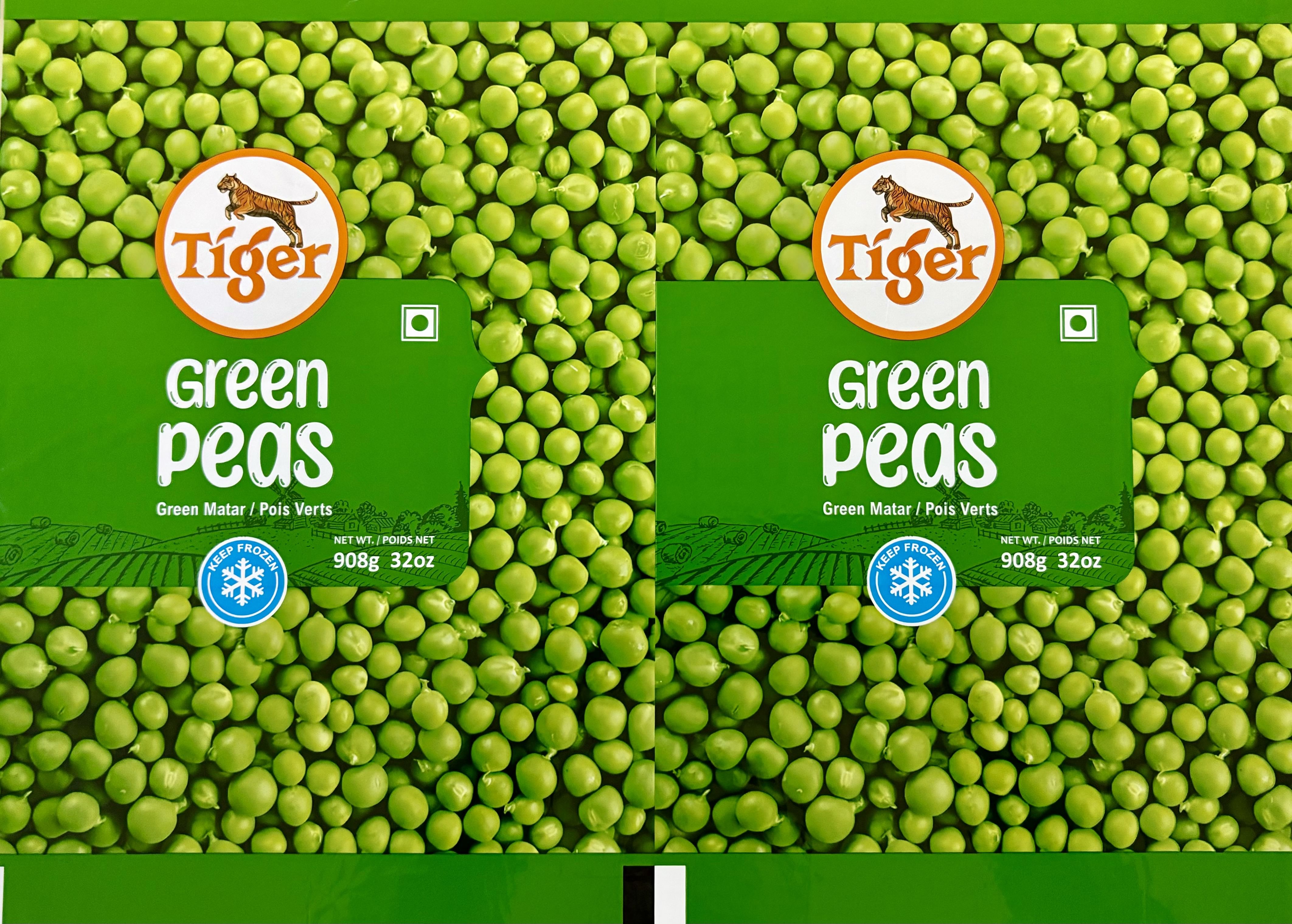

Brand: Tiger Green Peas frozen food; export-oriented

Packaging design: Mackin Design Studio

The market in India has a strong preference for gravure as the primary print process for flexible packaging. But trends point to flexography gaining market share. This will be accelerated by legislation, regulation and sustainability efforts by brands. The Indian industry is eyeing the space and more importantly hoping to leverage CI flexo’s tech-advantage. In fact this is what Ahmedabad-based flexible packaging company has achieved by setting a benchmark for flexo with “an impressive reproduction of 208 LPI print resolution”.

“The job was earlier printed on a rotogravure press. We converted this to flexo,” informs Jainam Shah, director of technology, Flexure Print N Pack. When asked about the need for 208 LPI, Shah explains the final goal was to achieve a printed sample with sharpness and details in images, but also to print clean.

He says that with the industry-average of 110 to 133 LPI in a CI flexo, we encounter strong competition from rotogravure converters as it is relatively simple to print higher resolution packaging designs in rotogravure because of its inherent characteristics.

Furthermore, he says when LPI is reduced; dot spacing is increased; dots become bigger in size and minute details of images are relatively lost. Therefore, 150 LPI and beyond is always preferable. “But with 208 LPI it is not only an achievement but also guarantees top quality for the A List brands,” Shah states.

So how did the team at Flexure Print N Pack work on the challenges and achieve this record?

208 LPI resolution printed job

Key features

“The client demanded a very high-resolution print on the job,” says Shah. He told us that the same packaging of frozen foods was earlier printed on a rotogravure press, and produced high quality results. He wanted to achieve a better quality with Flexure Print N Pack’s flexo set-up and expertise. He says, “In order to achieve the better result, we had to print the job at a high resolution and we opted for 208 LPI.”

“The acquired result provides details on the printed packaging material,” explains Shah. The packaging design has a monotonous colour tone with low contrast. Again, this was a challenge for the team. Shah says, “To achieve an appealing contrast was a big challenge. However, the main focus was details and sharpness.”

He pointed out that even the graphic design of the packaging played an important role in determining the resolution of the print. He says, “Since the job contained dominant colours, we decided this was the most suitable job for a 208 LPI resolution print.”

Shah expresses, “With this achievement by Flexure, I see immense potential for flexo to take over the flexible packaging market from rotogravure. This job will provide hope and new vision to the flexo players."

Today, 95% of the flexible packaging market belongs to rotogravure. Shah says, "The FMCG brands (big and small) focus on inventory management. Most brands seek better cost control. Plus there is a growing focus on sustainability. These are the primary factors for brands in order to address consumer needs, both external and internal (shareholders).”

He says the company’s mantra is, “Modern flexo which is capable of enabling process printing (four-colour and seven-colour ECG) with quick job changeover, greater process standardisation, high automation in print manufacturing, digitalisation and cost reduction.”

The make-ready time to develop a flexo plate is much less than a gravure cylinder. Shah adds, "Developing fine and desired quality output from flexo is difficult since it has a lot of variables, and it requires a holistic approach in print engineering."

For seven years, Flexure has been printing surface as well as reverse jobs with 150 LPI. This was taken forward with the reproduction of 175 LPI resolution by the Flexure team two years ago. The key, Shah says, is “The ability to image with precision and print accurately means being able to expand the tonal range, and print highlights, vignettes, linework and text with equal ease. This helps win more jobs, while also enabling the migration of jobs from other print processes to flexo.”

Challenges for this project

While running a multi-colour print job on flexo, the sequence of colours matters the most. Shah explains, “Since this was a reverse-printed job, it contained a darker to lighter process and spot inks were printed at 300 linear metre speed. Since, there is much less distance between subsequent print decks, adequate solvent evaporation should happen to avoid further challenges in the post-press operations. In addition to this at the same time, adequate ink drying was also ensured which otherwise could lead to poor ink trapping.

When printing with high-resolution, the dot sizes are reduced, hence the deposition of ink is being reduced and many such other variables were altered in the process in order to achieve the required high-resolution. Even with the reduced ink deposition, the optimum density was still achieved within the required tolerances.

Since the job was printed with a 208 LPI, Shah believes that there was a possibility of issues such as dot bridging and dirty printing. “A slight increase from the required ink and impression pressure would have resulted in mechanical dot gain which could have been enhanced with optical dot gain. The printed image would appear dark and lose contrast. Even the dot gains in highlights, midtones and shadows were observed well within standard tolerances,” Shah adds. He believes since it is printed at 208 LPI, the chances of facing these issues are more and the team has tried to control this in the press.

Since the process is well suited for short run jobs, it helps in reducing excess inventory for brand owners, and the wastage is reduced as compared to long run jobs

Customer feedback

The customer was said to have benefitted from many things, and thought of this project to be “value for money”. In normal flexo printing, because of the plate mounted on the sleeve, a hairline is present between subsequent prints. Shah explains Flexure avoided this hairline and provided seamless pouches with its technology.

He highlights certain advantages such as reduced turnaround time (TAT), low investment costs with multiple SKUs, low pre-press costs and CI flexo offering the freedom for short run jobs. “The similar job would result in 1.5x times the cost for rotogravure,” Shah adds.

Secret mantra on flexo

“Since there are a lot of variables in the flexo, process standardisation is very important,” says Shah. He adds that collaborations and tech-partnerships are a must to understand flexo better with correct process data, and experimentation about press behaviour is important. This, he says, will lower the learning curve and boost the industry.

Flexure is focused on R&D in pre-press and press-room to extract optimum performance out of the process variables even though it's integrated with CI flexo. “Developing a relationship between various parameters of the process is very important. A lot of trials are conducted with different types of variables and to test their compatibility with each-other is the area where we focus the most,” says Shah.

The higher the LPI, the lower the plate life. The industry has been responding to this in binary. Jainam Shah replies “yes and/or no”. “It does not necessarily hold true, it is a game of numbers. We have been using a plate of 150 LPI for the last two and a half years, while printing two tonnes per month. We have printed a total of sixty tonnes so far, and yet, the plate is performing exceptionally well,” Shah explains.

Plate handling, cleaning, storage and usage on the press “is a science” he believes. He highlights the misconception among converters who believe that printing with a higher LPI will produce smaller sized dots, which won’t get enough support on the plate. Hence, the dots are broken and not printed on the press due to non-uniform pressure dynamics. But he says, “If the converters are able to manage this, and crack the code, the statement won’t stand true.”

When asked about flexo’s sustainability quotient, he highlighted certain aspects. “Firstly the process is sustainable in terms of materials. Printing with water-based inks reduces overall environmental impact. Since the process is well suited for short run jobs, it helps in reducing excess inventory for brand owners, and the wastage is reduced as compared to long run jobs.”

Additionally, he says that the printing plates also move the needle by eliminating solvents from the plate-making process and thus making it sustainable.

Selection of process variables can drive standardisation efforts for optimum print results. For this Shah ensures there is a qualified and experienced technical applications team that can provide the right training and tools, while providing ongoing feedback through press trials and periodic pressroom audits. This, he says is the only way to ensure consistently accurate 1:1 print result reproduction from pre-press room to press room.

“Ultimately, our customer should be happy,” he says.

“And they can be happy only if we can guarantee precision and print quality with the best vignettes, line-work and text. This will help Flexure Print N Pack win more jobs, and simultaneously enable the migration of jobs from other print processes to flexo.” he signs off.

The flexible packaging company has been in the business for more than 40 years

Flexure Print N Pack profile

The flexible packaging company has been in the business for more than 40 years. It was set up by Ketu Shah, founder and chairman, who is a flexible packaging industry veteran. With his experience and knowledge in the industry, he now looks after the overall administration in the company. Ketu Shah believed in flexo, he always had a visionary mindset. Around 20 years ago, he started with the manufacturing set-up.

Rohan Shah, director of sales, Flexure Print N Pack, joined the family business in 2014, and is responsible for the business development of the organisation. He looks after the capital investments, revenue generation and guides the company towards growth.

Key services include packaging graphic design, printing, lamination, slitting, and converting. The company can print and manufacture end products from nearly all substrates such as BOPP, CPP, tubular quench PP (TQPP), polyester, LDPE, HMW HDPE, polyamide, paper, compostable and biodegradable plastics, and many more.

The company is planning to fix a new set-up to merge printed electronics in flexible packaging. One of the prime examples includes smart packaging. Flexure’s customer base includes food packaging majors; frozen foods, snacks, namkeen, spices and condiments; dairy; agriculture; textiles and garment; animal feed supplements and many more.

Talking about the company’s sustainability quotient, Shah says that it tries to reduce the carbon footprint by using recyclable and homogeneous materials' structure for their clients' needs. He says, “We are also shifting towards water-based inks for a better sustainability ratio, and a chemical recycling of solvents is being done.” There are activated carbon columns inside the manufacturing facility to remove organic and inorganic pollutants.

In terms of material development, Shah says that Flexure can design and provide materials as per client's final usage requirements. Flexure Print N Pack has machinery layout and storage facility for smooth material flow. It maintains hygienic conditions for manufacturing of food packaging materials. The company has adopted an environmentally friendly disposal system of production waste.

(l-r) Rohan Shah, director of sales; Ketu Shah, founder and chairman; Jainam Shah, director of technology