Flexo and gravure on par in terms of print quality, says Nilesh Pinto

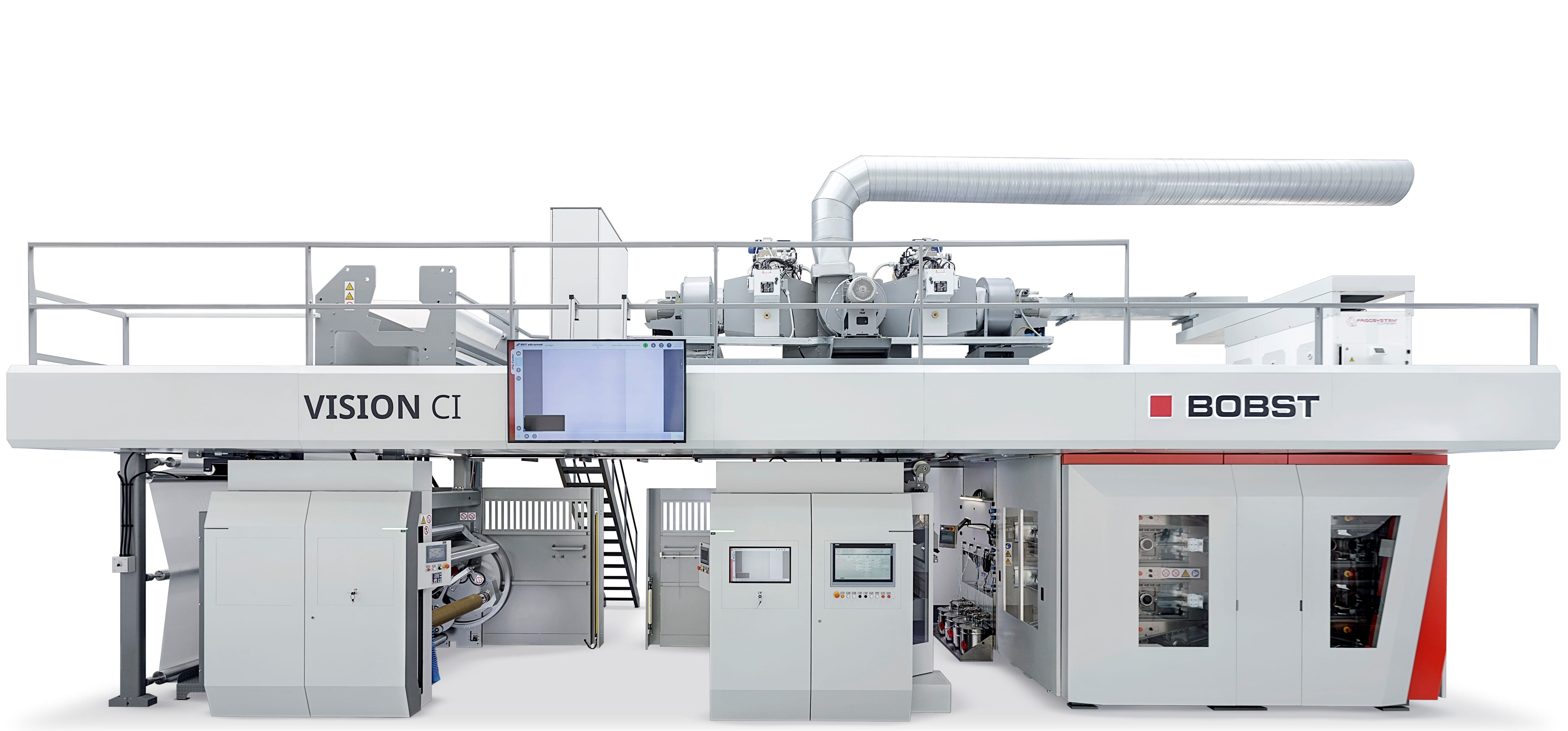

Today, CI flexo stands on the verge of the next big transition in flexible packaging. India needs people who can put the new technology to good use. Nilesh Pinto of Bobst India provides insights on Bobst’s latest Vision CI

18 Jul 2023 | By Abhay Avadhani

Abhay Avadhani (AA): How is the gap bridging between flexo and gravure?

Nilesh Pinto (NP): With the developments in both CI flexo and rotogravure technologies the clear cut difference is no longer the case. The gap between CI flexo and rotogravure has been closed in terms of printing quality. Each flexo printer has different requirements, materials, needs, and goals. It really depends on what best fits the plan of the printer and how, as an OEM, we can help them best fit their needs now, and in the future.

AA: Converters believe that, the finer the line screen, the better the image. In order to achieve high LPI, the press speed can be reduced, and does that not lead to a drop in efficiency?

NP: A higher LPI will not automatically lead to a better image. Printers need to find the right LPI level for their materials, jobs and customers’ requirements. High LPI will also be affected by the tools that one uses, for example anilox rolls. Bobst CI flexo presses are designed to give high quality print at top speeds.

AA: What are the process considerations in terms of cost, print quality and more?

NP: The printing technology is chosen to best suit the printing needs. Cost is not the only aspect. Sometimes it is the company or country legacy that defines the choice of technology, and most of the times it is the run length that defines the option. Typically shorter runs are assigned to CI flexo and longer runs to rotogravure, and more often than not, the technology choice is dictated by the brand owner. Traditionally, the rotogravure quality and consistency is set as a standard.

AA: There are trade shops in every major city who have flexo expertise. To what extent has the trade shop benefitted the CI flexo movement in India?

NP: From the product line perspective, we are not on the ground regionally. However, we have seen a great interest in CI flexo within India and we feel that trade shops have contributed to this interest. More engagement with the local market is always a great thing. We have an important presence in India to support all of our technologies.

AA: How much process control is required to get the expected performance out of the plate even though it's integrated with CI flexo?

NP: The flexo process has lots of tolerances; of plates, tapes, sleeves, adaptors, aniloxes and shafts. The question is how to minimise these tolerances and deal with them. Bobst CI flexo presses have one of the highest standards of manufacturing and assembly. Our offline impression and registering system, smartGPS measures the tolerances of the mounted flexo sleeve and calculates the optimal impression settings. It takes the tape, plate hardnesses and all tolerances into account. This gives printers the process control right at the start of the press and through the whole run.

AA: How can flexo become more popular with the implementation of EPR and single-use plastics ban?

NP: Bobst is focussed on sustainability; right from the production of our own equipment, including the supply chain, to the usage at our customers site. The company focuses on reducing energy consumption and waste, as well as enabling printing of the new sustainable recyclable substrates that are emerging. One of this year’s novelties is printing in CI flexo with our OneBarrier FibreCycle, which is a mono-web paper, high barrier recycle-ready solution. And this will be showcased in two live demos during our upcoming open house in Bielefeld on 26 October.

AA: What are the potential areas of automation in the flexo press?

NP: Automation in the flexo process, specifically CI flexo comes in the form of some Bobst technologies such as smartGPS and automatic mounting equipment. You will find automation all along the flexo workflow from prepress, to print, to quality control and lamination.

The Vision CI can be offered with smartGPS which is an offline impression and registering system that measures the tolerances of the mounted flexo sleeve and calculates the optimal impression settings

AA: How does screening impact the converters and what is the best technology out there?

NP: Not only a good, stable and robust press is key, but also a good pre-press. Today’s pre-press solutions offer all kinds of different micro screening. There is not a single technology that fits for all. The good thing about flexo is that there are lots of different solutions available to fulfil different tasks. Fine dots are printed more stable today and the ink laydown on the surface is much more homogeneous.

Functions of the press

The Bobst Vision CI press with GPS is a state-of-the-art press with a printing speed of 400-m/minute; the company can provide up to 500-m/min on special requests. It provides high quality print at top speeds with features such as oneECG and smartGPS. It can be used for CI flexo printing for food and non-food packaging applications; in reverse or surface printing, and also laminated or non-laminated products.

It provides a stable process control. The machine has an offline impression and register setting for low wastage and higher productivity. More jobs can be finished per day, and register and impression setting is done automatically independently of the operator.

It is aimed at flexible packaging markets in hygiene printing, paper printing; short, medium and long job runs. The Vision CI helps small producers to print high quality products at lower costs. The flexo process is not easy and with Vision CI, converters are able to manage this complex process very well.

Customer feedbacks

| Parakh Flexipack Parakh Flexipack is known in the market for high end quality and standards. “We have some of the leading and demanding customers for domestic as well as export business,” says Vinay Nalawade, CEO, Parakh Flexipack. “We went in for the first CI flexo press from Bobst in 2015 and are happy to receive the fourth printing press in our plant. The Bobst Vision CI press with GPS is a state-of-the-art press with a printing speed of 500-m/minute. All our investments with Bobst have been a success in terms of assurances and implementation,” he added. |

Rajhans Enterprises “We have installed two CI flexo presses from Bobst equipped with GPS. We believe in investing in the best technology across our group as a policy, and our quality and service is what helps us gain market and goodwill. We are very happy with our decision to go with Bobst and their service commitment has been great,” says Akash Balachandra, MD, Rajhans Enterprises, Bangalore. |