Dr NC Saha discusses raw materials for paper and packaging

Dr NC Saha shares his experience with the biomass project that focuses on paddy straws and stubbles as valuable raw materials for paper and packaging. Saha says paddy is one of the most important cereal crops cultivated globally. According to the United States Department of Agriculture (USDA), global rice production in 2023-24 was at a record 518.1-million tons (milled basis). In all this, India stood as the second largest producer of paddy in the world with a total production of 132 million tons (milled basis). How can paddy benefit the paper and packaging industry? Read on...

21 Nov 2024 | By WhatPackaging? Team

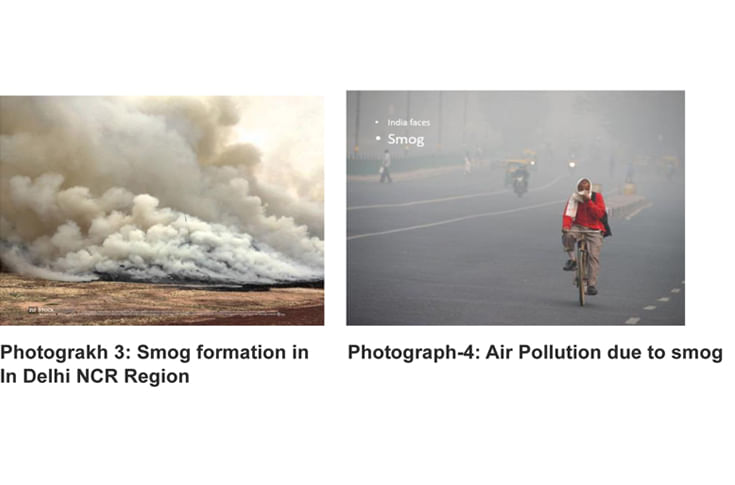

Paddy stubble burning and air pollution

Paddy straw and stubble are the parts of the paddy that have their roots in the earth. After harvesting the paddy crop, the farmers cut off its valuable upper part and some of the parts which are not useful, are left in the field. Paddy stubble is considered an agricultural waste in the world. Rice straw has a high C:N ratio and is more resistant to microbial degradation than other straws because its main constituents are cellulose and hemicelluloses encrusted by lignin.

India produces over 105-million tons of paddy yearly, producing about 200 million tons of paddy straw yearly. Paddy is grown in almost all major states of India. This is due to the consumption of rice which is a staple diet across the country. Out of a total of 200-million tons of paddy straw, 40-million tons of rice straw is burned annually. In India, paddy stubble burning poses challenges in north India, mainly Punjab and Haryana where the paddy and wheat cropping system is the focal issue. The quantity of the crop straw and stubble is staggering and the window for disposal is too small.

Burning of paddy stubbles in the field has become a common practice in the Indo-Gangetic plains during October and November to clear the fields for rabi crops (mainly wheat). Since the time window available between the harvesting of a paddy crop and the sowing of the next crop is short (2-3 weeks), burning is the preferred method. Moreover, the paddy stalk which remains on the field after harvesting of paddy and its removal is a labour-intensive process. Plus there is the festive season which results in the unavailability of labourers.

So, the time window for preparing the field for wheat cultivation is reduced, and the options that the farmer has are either investing in expensive and rarely used agricultural implements to remove the paddy stalks from the field or burning the paddy stalk and stubbles by setting fire to the field. Of the two, the latter option is cheaper and requires less effort.

A matter of concern across North India

A matter of concern across North India

The Indian farmer prefers the practice of the burning of paddy stubbles. But this results in air pollution and the release of greenhouse gas emissions (GHG) such as carbon dioxide and methane. This intensifies global warming and climate change and reduces soil fertility by depleting essential nutrients which are present in crop residue and human health like respiratory problems. This is rampant in Punjab, Haryana, Delhi and NCR region during the late September and October months and is a perennial problem in North India.

As per estimates, Punjab produces approximately 19-20 million tonnes of paddy straw and about 20 million tonnes of wheat straw. About 85-90 per cent of this paddy straw and stubble are burnt in the field and increasingly, wheat straw is being burnt during the rabi harvesting season. This problem also exists in Haryana, although the scale is smaller than in Punjab. When paddy straws and stubbles are burned, hazardous substances such as CO2, CH4, CO, and NO are released into the air as smog (less than 10 micrometre-sized particles). The burning of paddy straw has contributed to road accidents and health issues like respiratory problems among children and senior citizens residing in Haryana, Punjab and Delhi NCR.

This burning is the main cause of air pollution in Punjab and Haryana. This is of grave concern towards climate hazards which result in smog after burning. Smog is produced as a "toxic cloud" in New Delhi, resulting in declarations of an air pollution emergency. Its contribution to the poor air quality of Delhi is estimated between 25% to 30% on the days when stubble burning peaks in Punjab and Haryana. It severely affects the air quality in Punjab and Haryana which has a detrimental impact on soil fertility in terms of lack of nutrients.

This burning is the main cause of air pollution in Punjab and Haryana. This is of grave concern towards climate hazards which result in smog after burning. Smog is produced as a "toxic cloud" in New Delhi, resulting in declarations of an air pollution emergency. Its contribution to the poor air quality of Delhi is estimated between 25% to 30% on the days when stubble burning peaks in Punjab and Haryana. It severely affects the air quality in Punjab and Haryana which has a detrimental impact on soil fertility in terms of lack of nutrients.

The National Green Tribunal (NGT) has prohibited the burning of paddy straw and stubbles and passed directions including the imposition of environmental compensation against defaulters but any significant progress is yet to be seen.

Paddy stubbles into value-added products

Paddy stubbles into value-added products

Paddy straws and stubbles have high lignocellulosic materials which would be beneficial to create products. Also, various applications may be manufactured to convert this "agricultural waste into wealth" as high-value products.

Research in Haryana, identified a Dutch technological solution that can transform paddy straw into valuable applications ECOR technology can transform paddy straw into panels that can be used for furniture, gift boxes, doors, kitchens, displays etcetera. In addition, other circular products that could be made from the potentially removed paddy straw from the farm are packaging, paper and silica extraction.

On the one hand, the processing of the paddy straw, because of its high amounts of silica remains a great challenge. On the other hand, it is known that the extraction of silica from the paddy straw is viable, and it may be used in the production of car tyres and solar panels. These include energy generation, environmental adsorbents, building supplies, manufacturing of panels, conversion of crop residue into organic fertiliser, and valuable goods like tableware and cutleries for packaging application.

In fact, the use of paddy straw as fodder is not preferred by the farmers due to its high silica content in 100 kg i.e., 9.14% and hence, this material has got limited use as fodder as compared to wheat straw. As mentioned, silica content in paddy stubbles ranges from 9% to 20 % depending upon the geographical location.

Moreover, the chemical analysis indicates that paddy straw has 43.49% cellulose, 23.28% semi-cellulose, 4.8% lignin and 2.2 % protein content. Due to its high cellulose content, paddy straw would be considered a highly suitable material for making pulp for the paper industry.

As mentioned earlier, the main challenge is the presence of high silica content which causes constraints during the pulping process. Hence, the removal of silica from paddy straw has become a critical aspect. It is reported that Central Pulp and Paper Research Institute (CPPRI), an autonomous organisation under Govt of India developed the “desiliconisation” process by which silica content can be removed and paddy straw and stubbles can be made suitable for making pulp to produce paper.

This is an initiative by the MVO, Netherlands and The Embassy of the Royal Kingdom of Netherlands, Government of Netherlands.

The Indo-Dutch Sustainability Forum

The MVO Nederland is a sustainable business network in Europe. MVO Nederland, with the “Omzet met Impact” program, financed by the Netherlands Ministry of Foreign Affairs, identifies sustainable market opportunities and Corporate Social Responsibility risks in 12 countries on three continents. Dutch entrepreneurs work with local entrepreneurs and develop projects focused on sustainable sourcing, delivery and production, providing solutions to real-life problems.

India is one of the program countries of “Omzet met Impact”. In 2017, MVO Nederland carried out a Sustainable and Inclusive Business Scan, commissioned by the Netherlands Embassy in India. As a follow-up, the INDUS (Indo-Dutch Sustainability Forum) platform was developed, an online matchmaking platform. On this platform, Dutch and Indian business partners can tap each other, share sustainable challenges and solutions and work together on sustainable business cases. Within Indus, two pilot projects have been defined that act as a "showcase" for the active matchmaking of INDUS. The first one was the circular yarn project, and the other project was the valorisation of the paddy straw project. Both aimed to value-added products from agricultural biomass.

As a follow-up, in April 2019, MVO Netherland brought together a variety of market players, consisting of supply, technical solution providers and buyers to realise a new circular production chain based on the paddy straw. Indian and Dutch companies and organisations signed the “Partnership Agreement” with the ambition to validate the envisaged circular production chain and start to convert agricultural crop residue into value-added products.

Under the INDUS project, initiatives were taken as a pilot project for the usage of paddy straw and stubbles up to 10-15% for making pulp to produce paper. A few leading paper industries in India took trials for making paddy straw-based pulp for making writing paper and kraft paper for packaging applications. The initial trial was found to be successful and the quality of the writing paper and kraft paper were acceptable despite having the constraints due to the presence of silica content.

This is why, the desiliconisation technology needs to be adopted by the paper industries. This means they can convert paddy stubbles by using 10-15 % to make pulp for the production of paper for packaging applications so that paddy stubbles can be used as valuable raw material for the paper industry.

Kriya Labs, a start-up, founded in 2017 under the Technology Business Incubator Unit (TBIU) at IIT has developed a technology to convert rice straw into pulp which can be moulded into products like disposable tableware, sheets and packaging boards. These products made from paddy straw need to be commercialised.

Based on the successful trial project, it is concluded that the Indian paper industry should explore these possibilities to adopt the technology. This means the paddy stubbles as agricultural residue can be used as raw materials for paper for packaging applications.

Dr NC Saha is the founder-chairman of the Foundation for Innovative Packaging and Sustainability; a visiting professor of the Indian Institute of Management, Mumbai and former director at the Indian Institute of Packaging, Government of India.