Ashwini Deshpande: The most sustainable packaging will be “no packaging”

Co-founder and director of Elephant, Ashwini Deshpande reports from Interpack, held May 4–10 in Düsseldorf and focuses on technologies and sustainability and connected packaging, as well as what more can India do

31 May 2023 | By Ramu Ramanathan

Ramu Ramanathan (RR). Back after six years. What was the Interpack highlight for you?

Ashwini Deshpande (AD): As you may be aware, we handle a significant number of packaging design projects at Elephant. We are engaged in packaging structure innovations as well as branding and communication design for packaging. It is one of the thriving verticals within our multiple offerings. What makes us a leading packaging design agency is perhaps the fact that we try to take our client partners and their consumers ahead of the curve.

RR: You have visited Interpack earlier?

AD: I had visited Interpack, a few years ago for two consecutive seasons. It is the biggest and most diverse exposition of packaging material, processes and machinery. It is very impressive. But after a point, one could see everything virtually. So I stopped visiting.

RR: Then why did you decide to visit this time?

AD: Interpack was transpiring after a long gap and I believed one would see a leap in thinking about packaging as a concept itself. Sustainability and connected packaging, the two key themes of Interpack caught my interest. Both these are experiential when it comes to packaging. Also, we have an increasing awareness and intent towards both these themes in India. So it seemed like a good opportunity to visit the fair this year.

The major focus is on innovation in shipper packaging, shipper tapes and closures

RR: Which technologies caught your attention and why?

AD: It is very evident that eCommerce is the new order. So the major focus is on innovation in shipper packaging, shipper tapes and closures. I will not pinpoint specific brands or companies.

RR: Okay, fair enough.

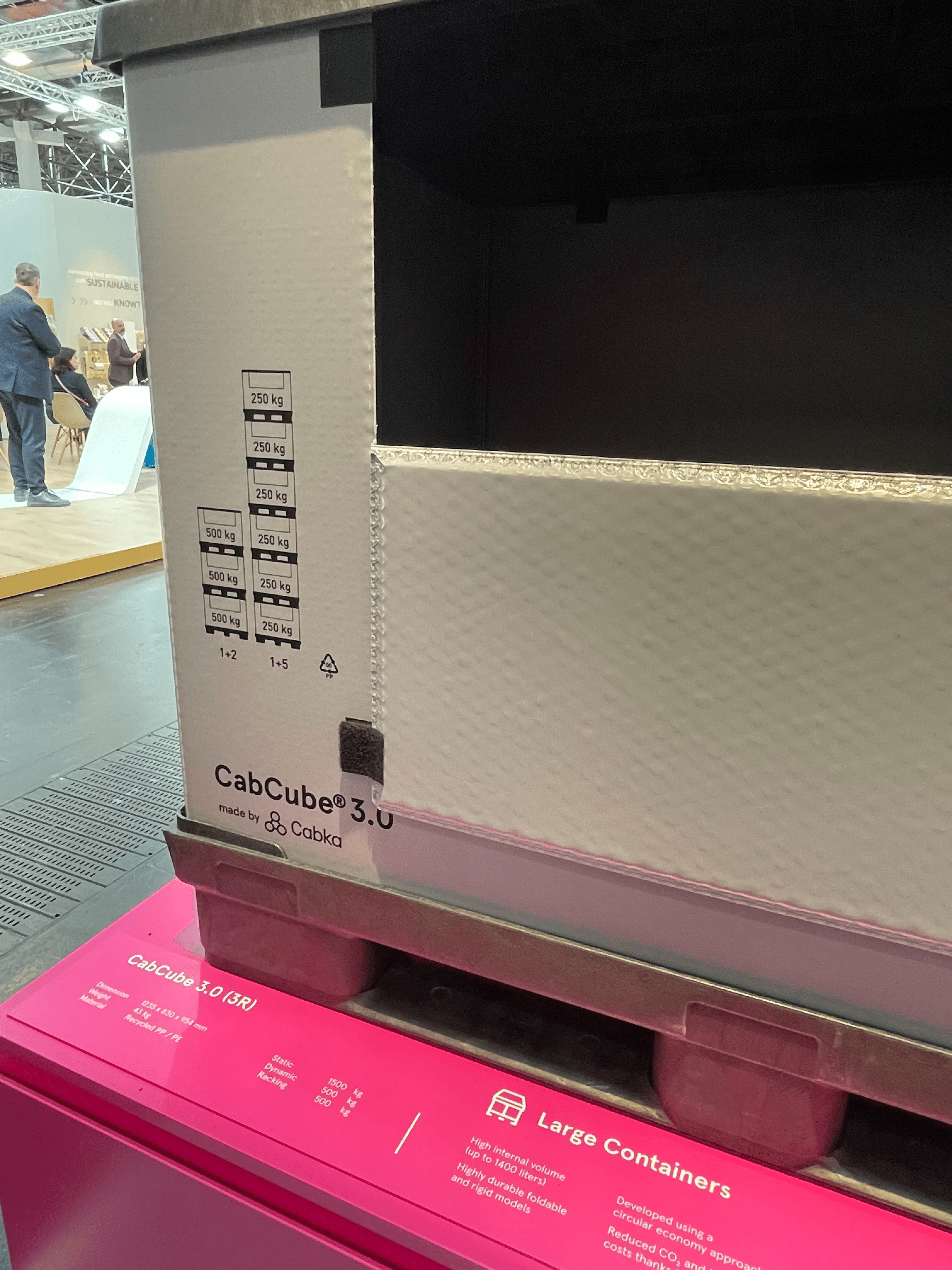

AD: I am listing three areas where most innovation is happening resulting in sustainable consumption and practices. Surprising as it may sound, packing tapes and sealing systems are seeing their moment. With so much secondary/ tertiary packaging required by eCommerce players, consumption of tapes has sky-rocketed. Also it is being seen as one of the elements for conversion to sustainable materials and practices. The next surprise was the colour pigments used in caps and closures of PET packaging. There is a lot of ongoing research and exploration happening within this space that will go a long way in making recycling more sustainable. And finally, shipper crates and cartons is the third big area where reducing or replacing material with sustainable alternatives is being tested along with ways of making reuse feasible.

RR: More than 116 Indian manufacturers at the Interpack show. Good news for the Indian packaging industry or still some way to go?

AD: Though Turkey was the focus country and managed to grab the optics at all vantage points, it was wonderful to see a large Indian participation. However, the layouts, displays and Indian identity were quite inconsistent. I am sure many of them would have figured that their booths need to be far more sophisticated than what went on display this year.

RR: Sustainable ideas you believe would make a difference if the Indian packaging fraternity learns to adopt from Interpack?

AD: Recycling must make business sense for it to become mainstream, and not remain a hobby project or ESG greenwashing. After going through the developments, especially in Europe, I believe the ecosystem of trash collection to bring back a product with recycled materials needs to be very robust. It cannot be done by the packaging fraternity alone. It needs systemic advocacy and change. The responsible FMCG leaders need to make a genuine attempt for such a development taking innovators, consumers, converters and policy-makers along.

Innovation is happening in packing tapes and sealing systems due to rising demand from eCommerce players

RR: How do we de-risk design innovation?

AD: Not all innovations need to be radical or disruptive. Some can be incremental, and yet make a huge difference. Any new development that starts with a real human need and solves for a need-gap can be called an innovation. The idea either needs to solve an old problem in a new and better way or a new problem in a smart way. However, the innovation journey needs to be taken up with a developmental and exploratory mindset. It is unpredictable. It requires patience and investment of resources. It cannot be planned as a quarterly objective. James Dyson made 5000+ prototypes before launching his (now) legendary bagless vacuum cleaner. His net worth is a billion dollars.

RR: Possible to have a design guideline to create sustainable packaging?

AD: Absolutely. I would put down a four point agenda for developing a sustainable packaging based on what I grasped at Interpack. It should be possible to pick any one and go deeper. These are: biobased; recycled; biodegradable; compostable.

RR: What should India's plans be for Interpack 2026? One suggestion ...

AD: Go big. Go together.

RR: And finally, one AHA thing you overheard at the show.

AD: The most sustainable packaging will be “no packaging”.

.jpg)

The ecosystem of trash collection to bring back a product with recycled materials needs to be very robust